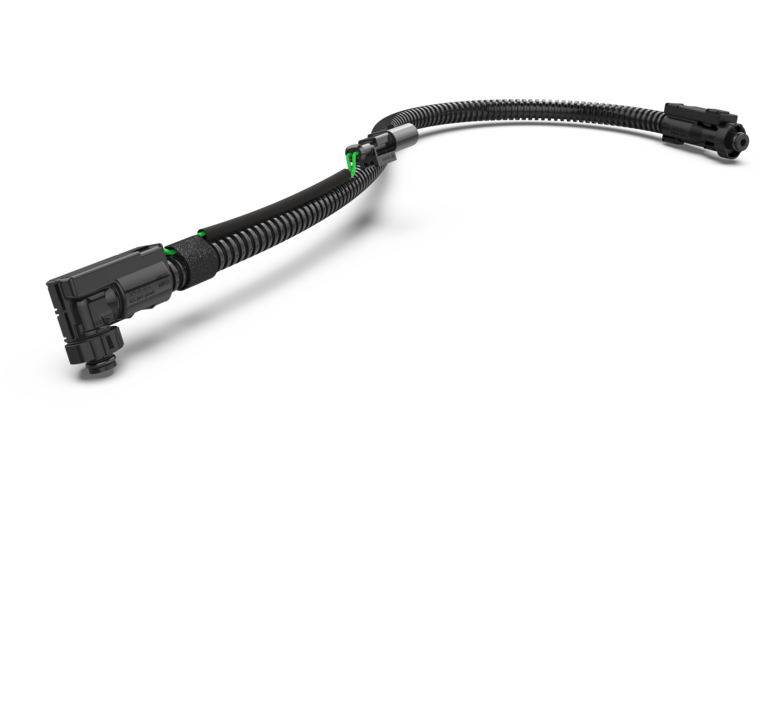

VOSSLok40 tube forming system

The VOSSLok40 tube forming system is our innovative and economical connection solution that offers maximum tightness and safety. VOSSLok40 is the ideal choice, especially for media that place higher demands on leakage resistance.

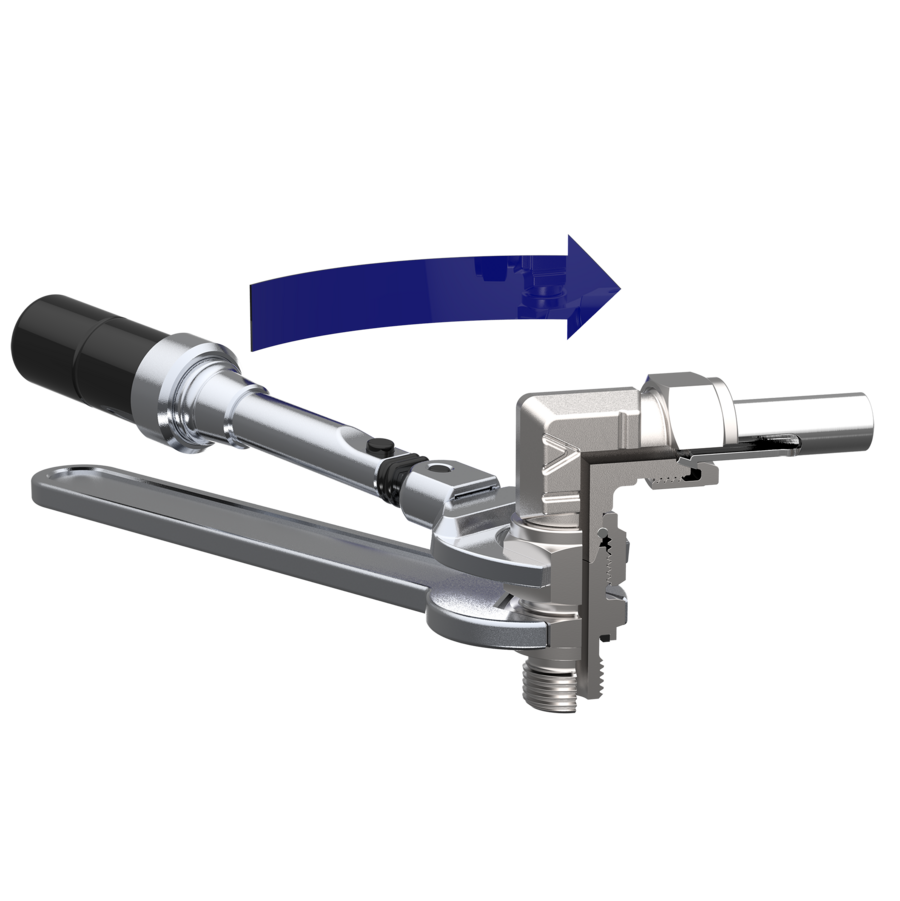

The VOSSLok40 tube forming system is based on our many years of experience with connection components and tube forming systems. The VOSSLok40 forming machine is used to form a sealing and retaining contour at the end of the tube. This mechanical tube forming process compacts the material on the tube surface and at the same time smooths the sealing radius. This eliminates surface defects on the tube and achieves excellent tightness.

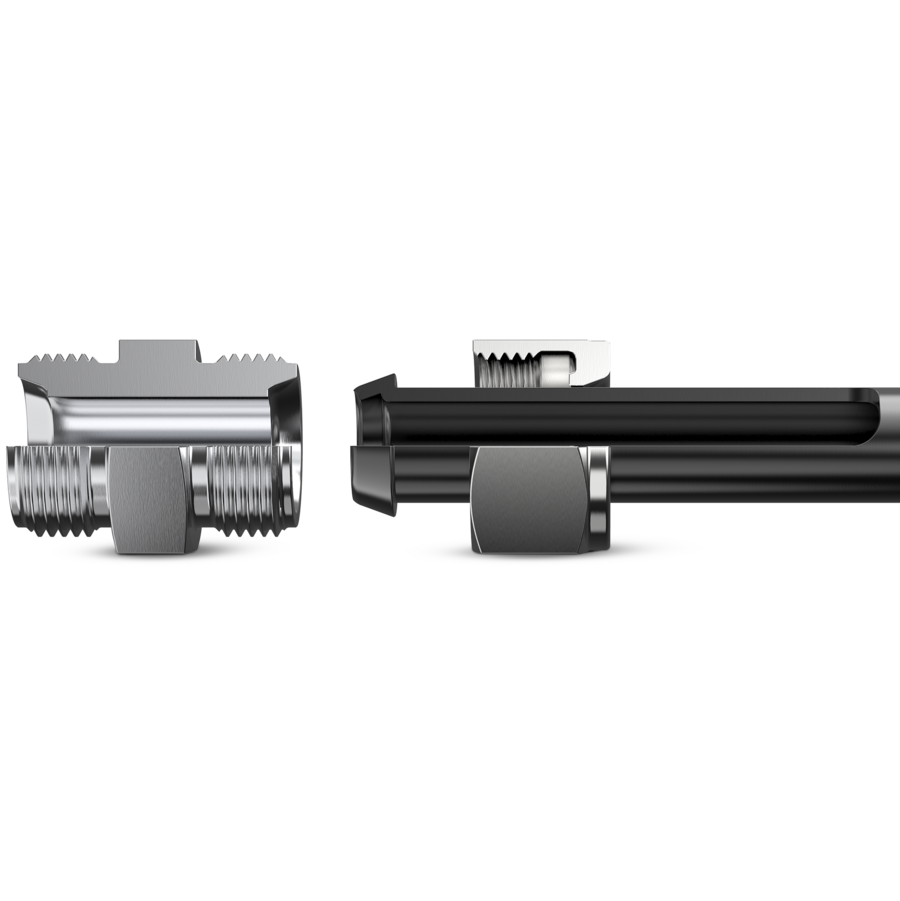

The screw connection of the VOSSLok40 system and the tube contour are matched to each other in such a way that the sealing surfaces are compressed to a very high degree, thus ensuring optimum sealing of the only possible leakage path.

The result: a connection solution that guarantees maximum leakage safety even under the most demanding conditions - for example when used in hydrogen and CNG applications.

Product advantages

Maximum process reliability in assembly

Machine forming and the specified tool contour ensure that the VOSSLok40 geometry is always correctly executed. In addition, the integrated "soft" block stop effectively prevents assembly errors during the final tightening of the connection.

Pressure-resistant and leak-proof

The superior quality of the sealing surfaces allows for precise rod sealing of the sole possible leakage path. This ensures maximum leakage safety, particularly when used with gaseous media such as natural gas or hydrogen, thanks to the VOSSLok40.

Highest economic efficiency

The VOSSLok40 tube forming system is a particularly advantageous connection solution due to its high leakage resistance, shorter installation times and ease of maintenance.

Quick and easy installation

The mechanical tube forming process is particularly intuitive and therefore very easy to learn. This increases process reliability and greatly reduces cycle times.

Quality-assured final assembly

Final assembly using torque is also possible, making every connection result verifiable. This is a great relief for the fitter and a considerable advantage for internal quality control.

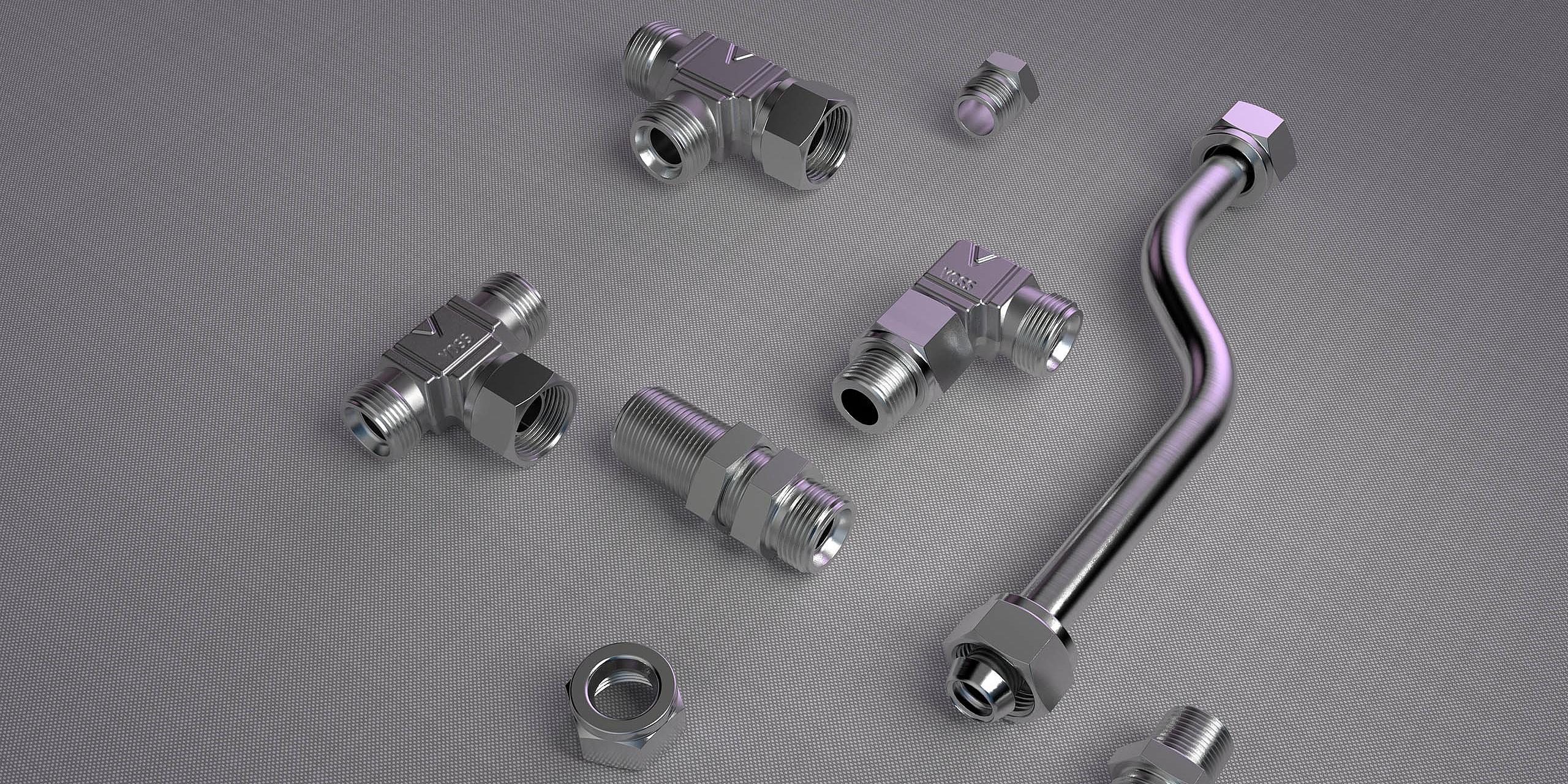

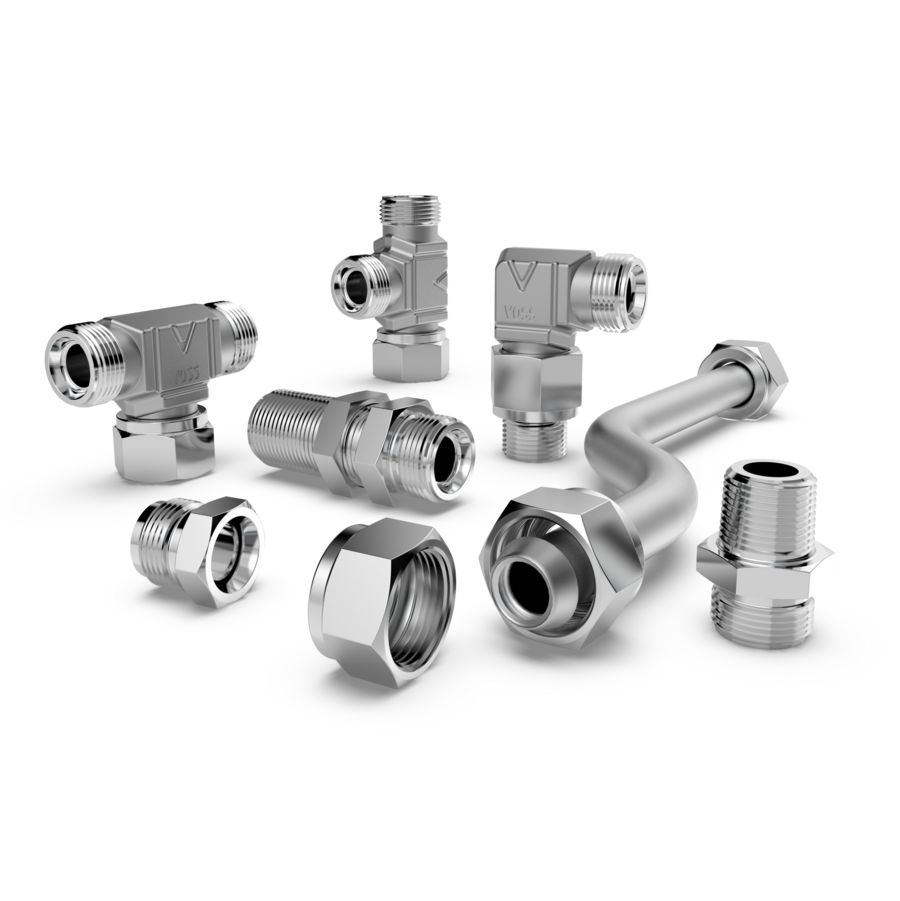

Wide product range

The VOSSLok40 connection system has a variety of shapes and connection types for a wide range of tube diameters and wall thicknesses.

Technical data

Material

Stainless steel according to specification

Dimensions

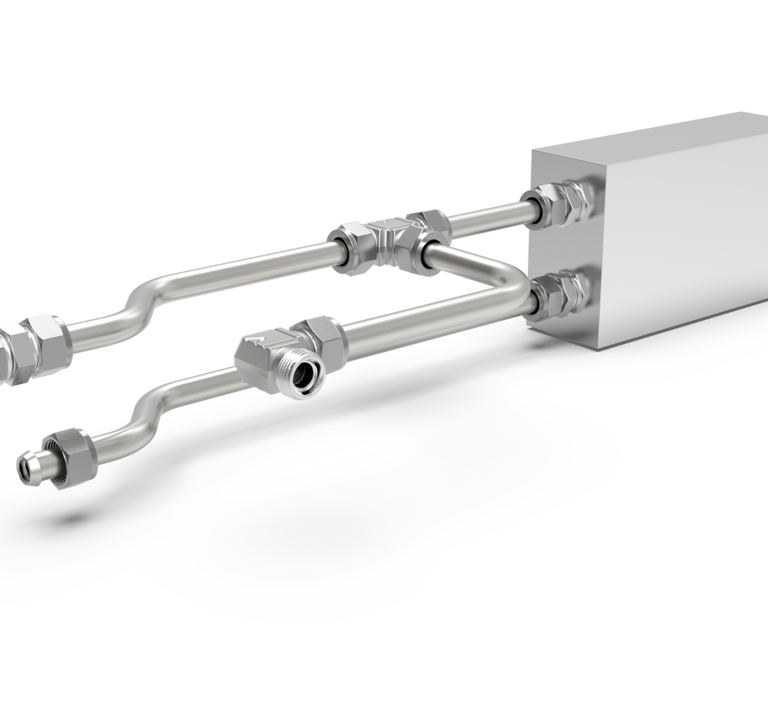

For tubes made of stainless steel 1.4571 - tube OD 6mm - 22mm

Details at a glance

Find out more about the advantages of our VOSSLok40 tube forming system

The extensive product range

The extensive VOSSLok40 system includes a wide variety of designs, e.g. angle, T or L fittings. The system components are available with different outer diameters.

Economic added value

The cost-effectiveness of a connection system is influenced by many factors. With VOSSLok40 you can successfully prevent leaks and thus reduce the associated costly complaints. The simple assembly increases your product quality, assembly times are greatly reduced and the elimination of clamping and wedge rings eliminates costs for disposition and storage.

Versatile and flexible in use

The compatible VOSSLok40 system can also be used in combination with commercially available compression fittings. Many of the advantages of the connection system remain.

Typical applications

The VOSSLok40 tube forming system is our leak-proof connection for demanding media.

Electrolysis and refueling systems

Whether in a liquid or gaseous state. The VOSSLok40 tube forming system is ideal for the safe use of hydrogen (H2), CNG or other gases.

Trucks and buses

Reproducible results are particularly important in series production. VOSS Lok40 offers maximum process reliability and functionality, also in the areas of WHR (waste heat recovery), CNG or hydrogen fuel cells. Added to this are the particularly simple and user-friendly preassembly principle and very short cycle times.

Power generation

The VOSSLok40 tube forming system, which has been approved by independent testing companies, offers the highest degree of leak-tightness for safe use with compressed air, natural gas (CNG), liquefied petroleum gas (LPG) and hydrogen (H2).

Product videos and CAD data

Discover the benefits and assembly information of our innovative products in video format and access our extensive CAD database - free of charge and in the highest quality.

Please always observe the current operating and assembly instructions when handling VOSS preassembly devices, tools and products.

Matching products

Our approach is holistic. In addition to a wide range of suitable connection components, VOSS offers an extensive portfolio of preassembly devices, tools and aids.