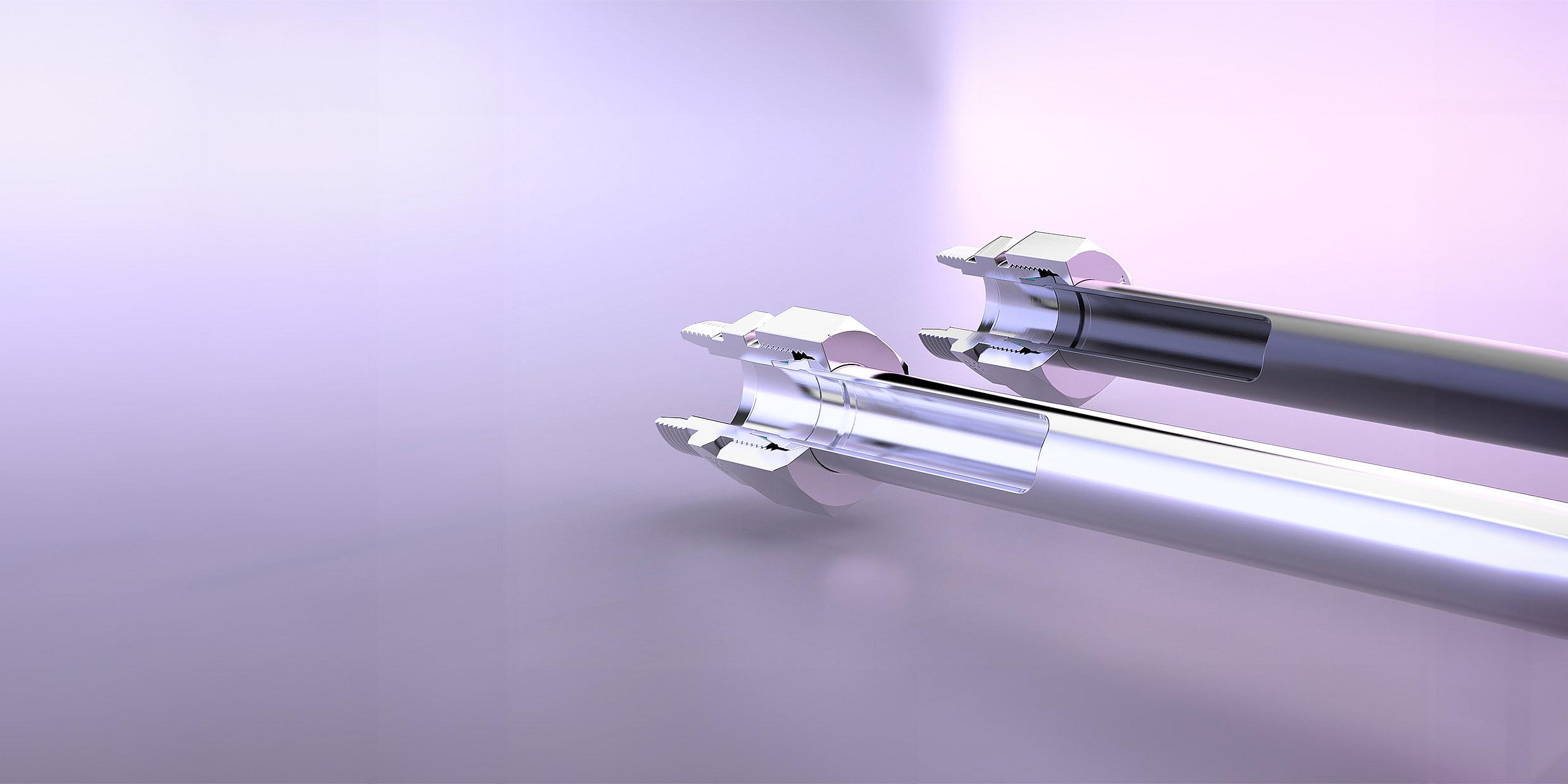

Tube forming system VOSSFormSQR (VA)

The innovative and particularly economical tube forming system for hydraulic tubes made of steel and stainless steel. Sophisticated pre- and final assembly and outstanding leakage safety offer optimum production quality in your series production.

When the product was launched more than twenty years ago, we already knew that the VOSSFormSQR tube forming system had set a milestone in joining technology. This is why VOSSFormSQR confidently bears the essential requirements for hydraulic connection technology in its name:

Safety - the most important aspect

Quality - without which permanent freedom from leaks cannot be possible

Profitability - only an economical bolting system can hold its own in the market

Over two decades ago, our VOSSFormSQR tube forming system began its unprecedented triumphal march and, with its ingenious design principle, ensures millions of permanently leak-free joints. This impressive performance is guaranteed not only by the metallic seal with additional FKM soft seal, but also by the wide tube support provided by the SQR functional nut. This effectively dissipates the highest dynamic loads, such as vibrations or spontaneous load changes, from the connection area. The simple forming and assembly principle also ensures maximum process reliability in preassembly and final assembly.

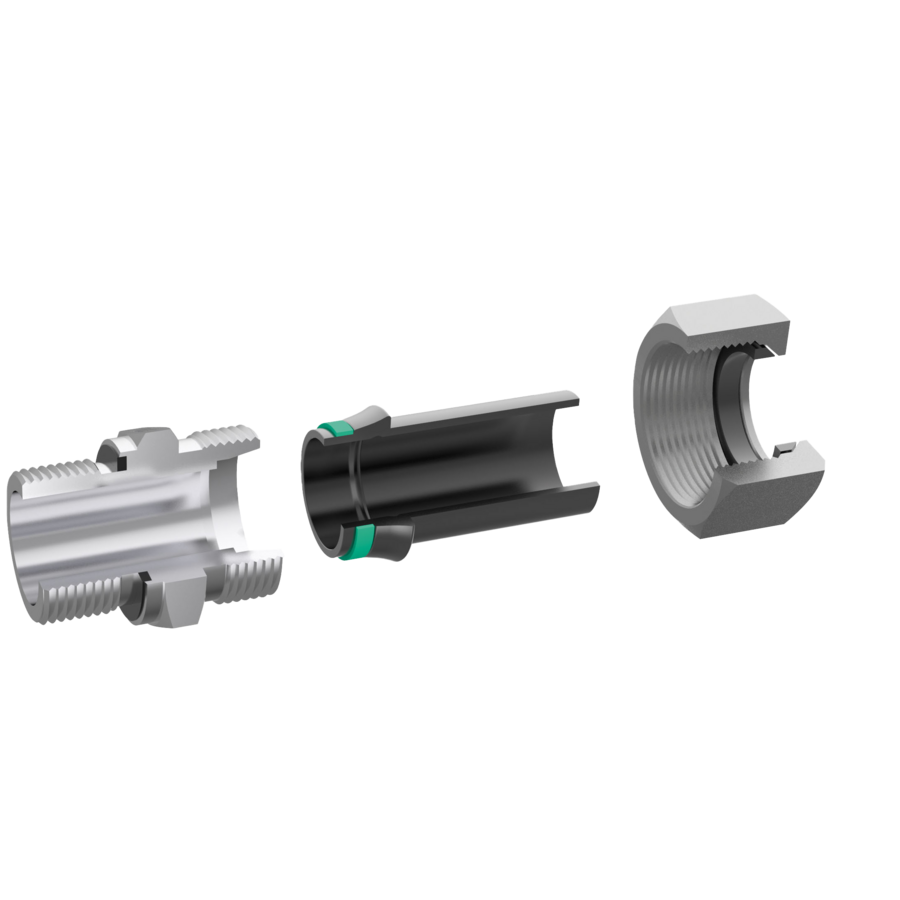

With its innovative design, VOSSFormSQRis based on the proven VOSS construction principles. A 24° tube contour is formed at the end of a standard hydraulic tube using the VOSS Form 100 forming device. Supplemented by an additional soft seal and the special SQR functional nut, a simple and high-quality connection is created for maximum load-bearing capacity and safety. The system is characterized above all by its high process reliability during assembly - combined with all the advantages of the VOSS DKO principle - short tightening distances, noticeable increase in force to avoid over-assembly and maximum tightness due to metallic sealing with additional soft seal.

The VOSSFormSQR tube forming system with all its advantages is also available for stainless steel components.

Product advantages

Our VOSSFormSQR (VA) system offers significant added value compared to conventional connection systems.

Highest leakage safety

The combination of a metallic seal with an additional soft seal ensures an ultra-fine seal, even under the highest pressure loads and dynamic stresses.

Pressure-resistant and unbreakable

The SQR functional nut with integrated clamping ring clamps the tube around the circumference radially and thus absorbs dynamic loads before the critical area.

Economic efficiency

The high level of leakage safety, shorter installation time and ease of maintenance make VOSSFormSQR tube fittings an advantageous solution.

Simple preassembly

The tube forming process is particularly intuitive and therefore extremely simple. This increases process reliability in production and greatly reduces cycle times.

Reliable final assembly

VOSSFormSQR provides the user with direct feedback and thus, in addition to shorter assembly paths and reduced assembly times, also noticeable under- and over-assembly protection.

Wide product range

The VOSSFormSQR system is based on standard components. The complete VOSS DIN/ISO program is therefore available for the VOSSFormSQR system.

Technical data

Material

Hydraulic tubes made of steel and stainless steel according to specification, soft seal made of FKM.

Max. operating pressure

Up to 500 bar in the "L" series, up to 800 bar in the "S" series

Dimensions

For stainless steel tubes - tube OD 6mm - 42mm

More detailed information

Details at a glance

Find out more about the advantages of our VOSSFormSQR tube forming system.

VOSSFormSQRVA system for tube forming

VOSSFormSQR is a reliable system which, with its easy-to-install design and special construction, ensures a secure and permanently leak-free connection even under extreme conditions.

Stainless and with VOSS spring effect

The forming process with the VOSS Form 100 forming machine is extremely simple. The simple insertion of the tube end against the stop plate and the monitored forming process do not allow for any errors. The inner mandrel on the upsetting head prevents constriction of the tube in the formed area. The internal tube diameter remains

completely - there can be no pressure loss due to bulging. Cycle times of 7 to 15 seconds significantly reduce assembly times, especially in series production.

Available in steel and stainless steel

The VOSSFormSQRVA forming system is available for applications in stainless steel. All individual parts are made of stainless steel. The same product properties and advantages apply as for VOSSFormSQR for applications in steel.

Assembly videos

Discover the benefits and assembly information of our innovative products in video format and access our extensive CAD database - free of charge and in the highest quality.

Please always observe the current operating and assembly instructions when handling VOSS preassembly devices, tools and products.

Typical applications

The innovative and particularly economical tube forming system for hydraulic tubes demonstrates its advantages in many applications.

Marine and offshore

Whether below or on deck, VOSSFormSQR (VA) offers a particularly durable seal for use in shipbuilding and port technology, especially in harsh and corrosive outdoor conditions.

Stationary machinery

Due to its short tightening paths, the VOSSFormSQR forming system offers reliable and leak-free connections even in confined installation situations.

Mobile machinery

Reproducible results are particularly important in series production.VOSSFormSQR offers short cycle times with consistent quality due to its particularly simple and user-friendly preassembly principle.

Matching products

Our approach is holistic. In addition to a wide range of suitable connection components, VOSS offers an extensive portfolio of preassembly devices, tools and aids.