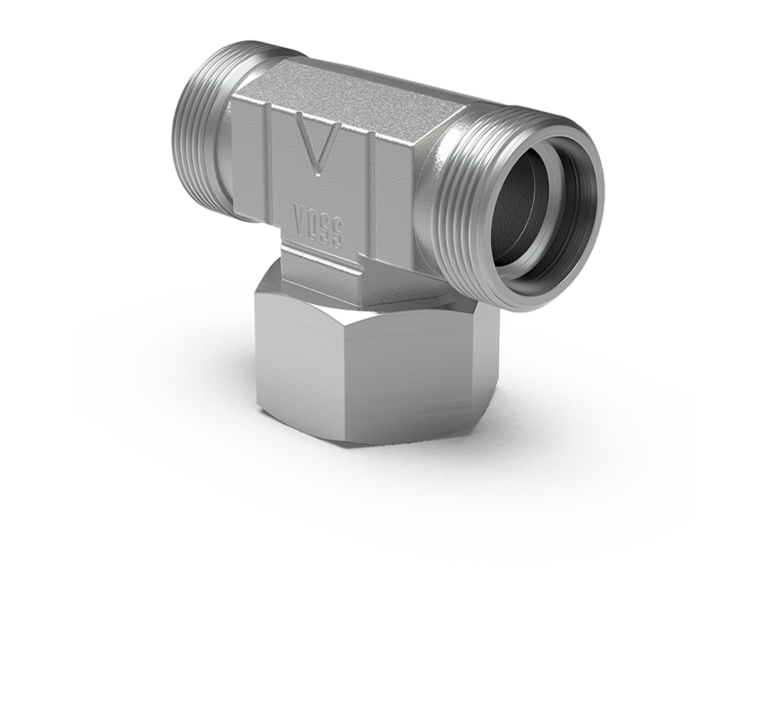

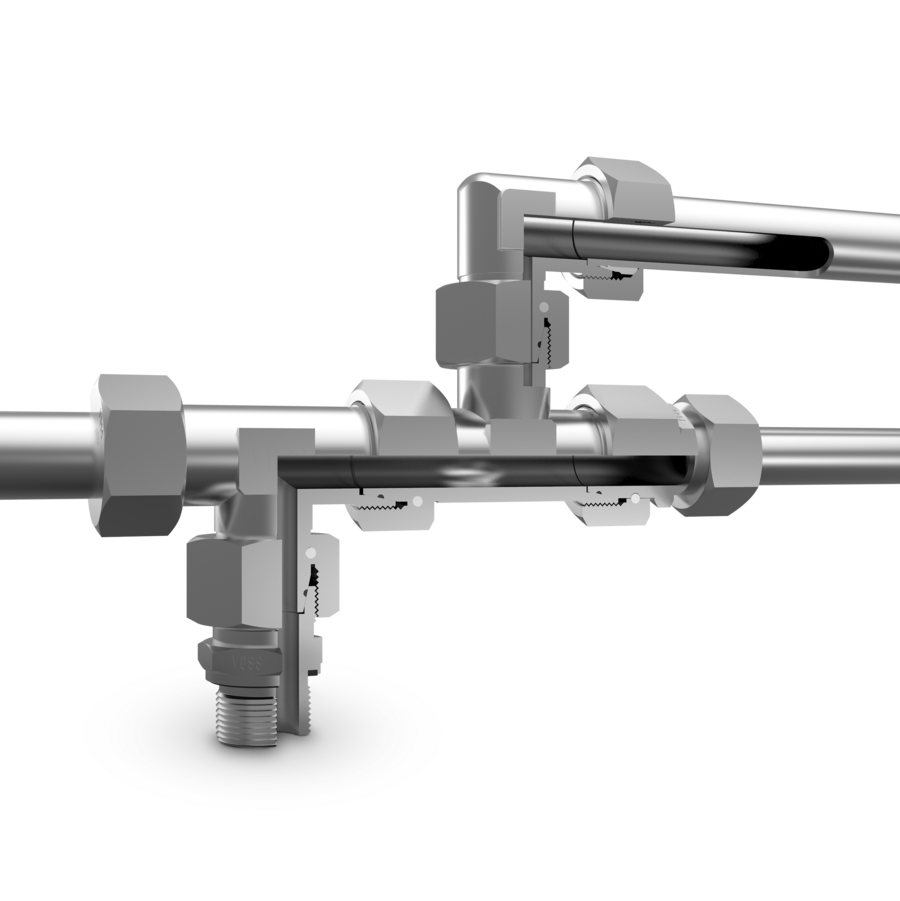

Sealing cone fitting VOSS DKO

The VOSS sealing cone fitting offers maximum security against incorrect installation and leaks. The unbeatable installation advantages and the DKO sealing principle with additional chambered soft seal effectively prevent leaks.

The 24° sealing cone fitting is a logical further development of the adjustable fitting with tube shoulder and preassembled cutting ring, which are also included in the extensive range of VOSS tube fittings. The sealing cone attached to the fitting body ensures a particularly secure and permanently stable connection.

VOSS DKO sealing cone fittings can be installed easily and reliably due to short installation paths and tightening torques. The sealing cone attached to the fitting body ensures a particularly secure and permanently stable connection.

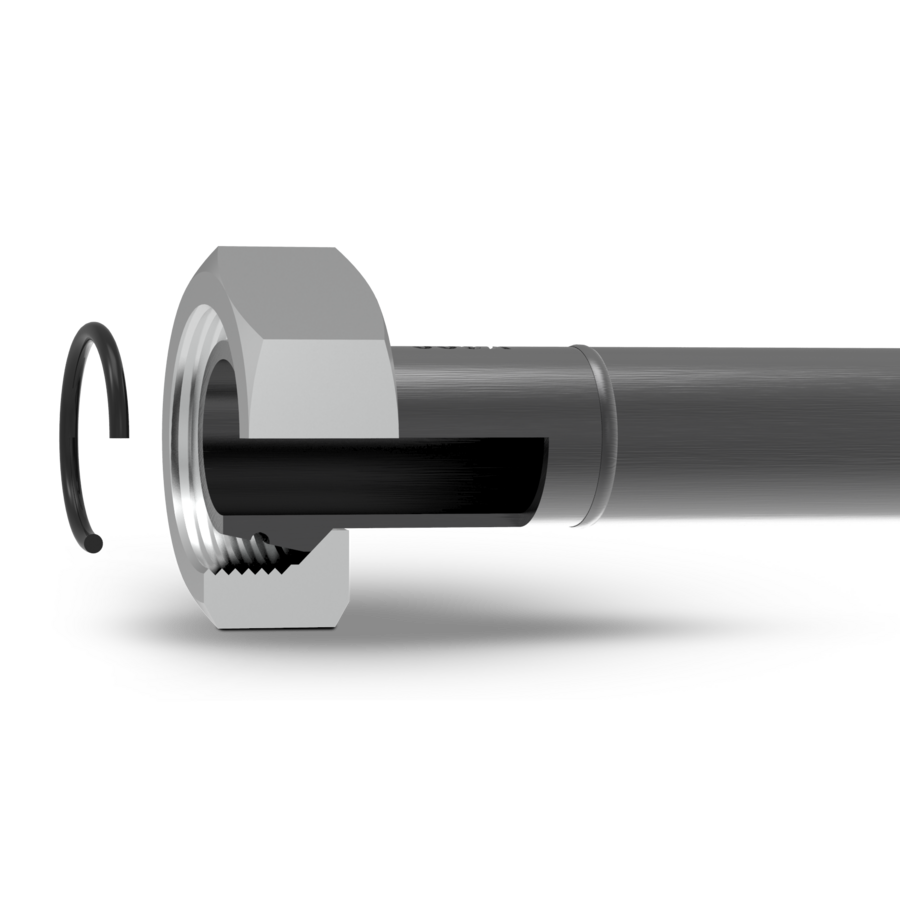

The retaining function is performed by a special union nut with a wire pin located in a groove. After final assembly, the positive-locking union nut ensures a tear-proof connection. The sealing function is provided by the chambered O-ring. This achieves an ideal ultra-fine seal. With a wide range of different designs and connection sizes from 6 to 42 mm outside tube diameter, all common combinations of direction-adjustable fittings can be produced. The connection dimensions correspond exactly to DIN 2353 / ISO 8434-1. This makes it interchangeable with the traditional adjustable shaft version.

Product advantages

Highest leakage safety

Maximum leakage safety due to metallic seal with additional soft seal

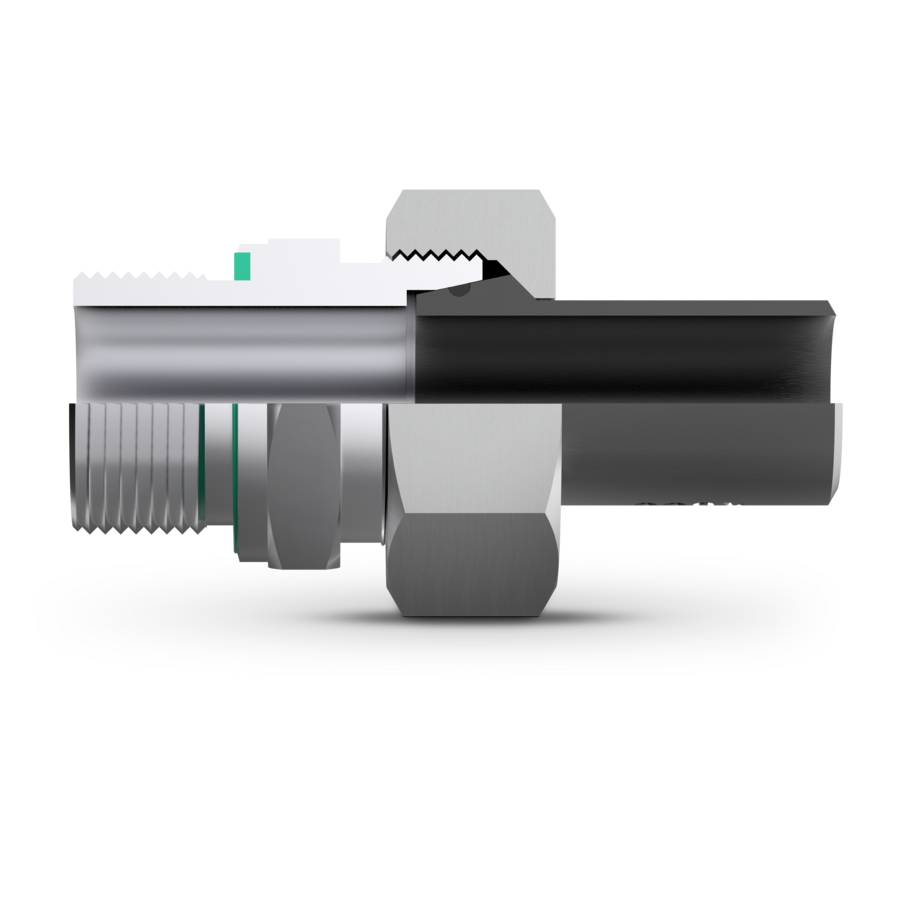

Short pull-in distances

All VOSS DKO connections have greatly shortened tightening paths. This significantly reduces the work involved in assembly.

Reduced tightening forces

VOSS DKO connections require less force for tightening, offering a significant advantage in challenging installation conditions.

Flexible in use

The VOSS range of sealing cone fittings offers various designs and dimensions, providing designers with maximum flexibility in machine and system design.

Overassembly protection

The integrated tightening limiter effectively prevents over-assembly.

Corrosion protection in perfection

VOSS DKO sealing cone fittings are protected against corrosion with VOSS coat as standard.

Technical data

Material

VOSS-specified special material with VOSS coat corrosion protection

Max. operating pressure

Up to 500 bar in the "L" series, up to 800 bar in the "S" series

Dimensions

For steel tubes - tube OD 6mm - 42mm

Details at a glance

Find out more about the advantages of our sealing cone fitting VOSS DKO

Leak-proof, even under demanding conditions

The sealing effect of VOSS sealing cone fittings remains high and reliable even under high dynamic loads, vibrations and pressure surges. The chambered soft seal provides additional leakage safety.

A sustainable and economical alternative

The VOSS DKO system is one of the most secure connection types for DIN/ISO standardized threaded nipples with 24° cone. The proven DKO sealing head with additional soft seal performs the sealing function on the nozzle.

Reduced assembly distances and tightening forces

The required tightening distances and assembly forces for VOSS sealing cone screw connections are lower than for conventional connection types, for example for shaft versions with cutting ring connections. This creates secure connections, especially under difficult installation conditions.

Assembly videos

You can find information on installing our products here in video format. Please always observe the current operating and assembly instructions when handling VOSS preassembly devices, tools and products.

Typical applications

VOSS DKO sealing cone fittings can be installed easily and reliably due to short installation paths and tightening torques.

Mobile machinery

When it comes to safe functional performance under the tightest installation conditions.

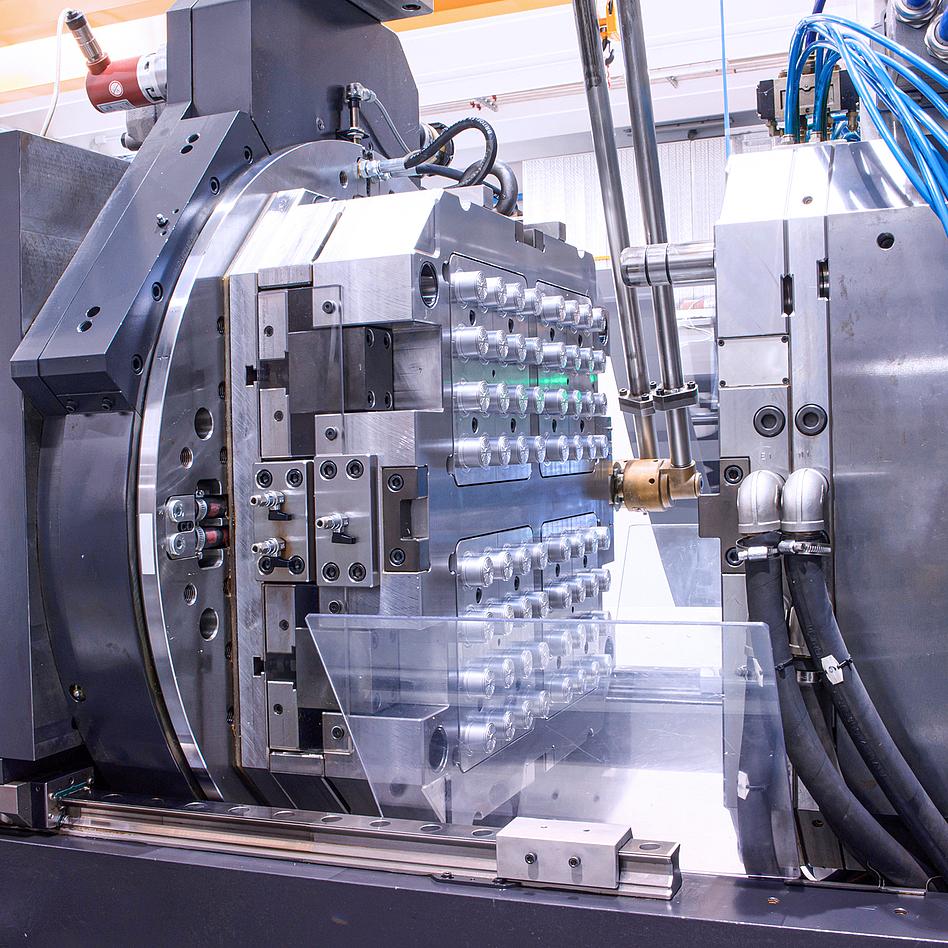

Plastic machines

When secure connections are required with constant load changes and pressure peaks.

Agriculture

The robust connection solution when it comes to maximum reliability under mechanical loads.

Matching products

Our approach is holistic. In addition to a wide range of suitable connection components, VOSS offers an extensive portfolio of preassembly devices, tools and aids.