Measuring couplingsVOSSPointDC

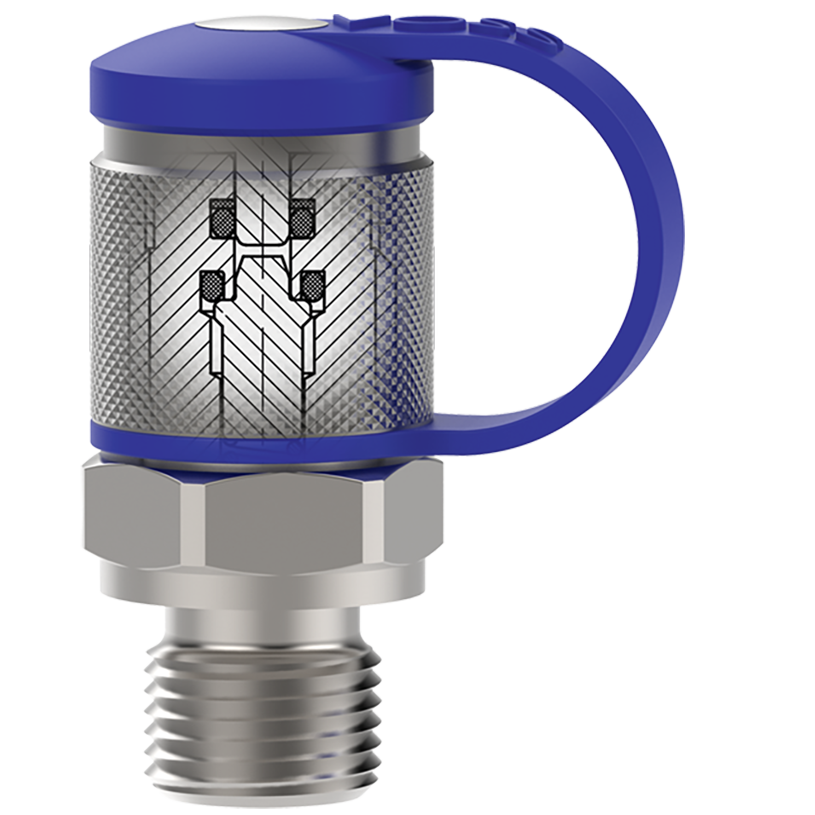

We are redefining the safety and handling of measuring couplings by reimagining existing technical solutions and incorporating our superior VOSS coat coating. The result: Our measuring couplings provide near-complete leak-free performance during coupling and uncoupling - even under pressure and during system operation.

Experience plus ideas

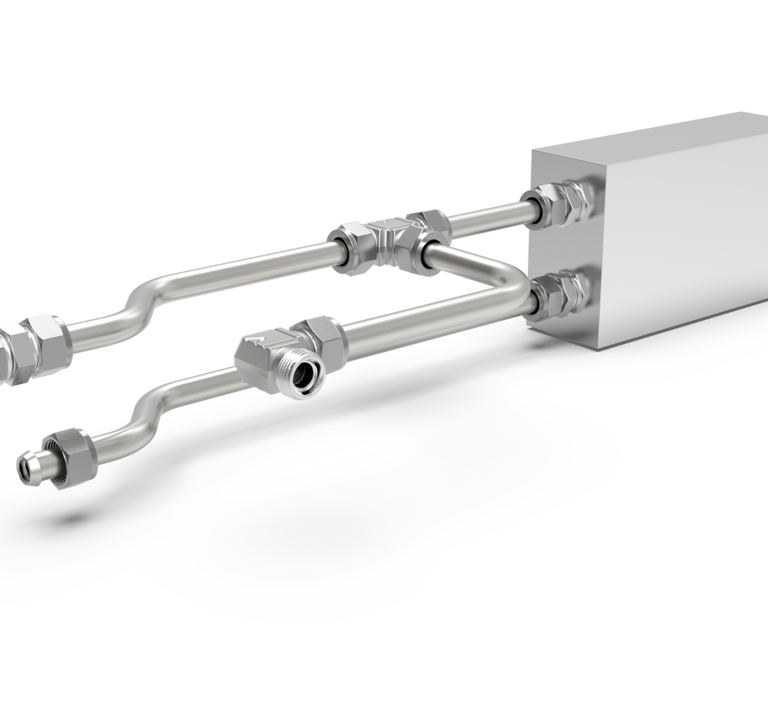

Pressure testing in hydraulic systems is extremely important for smooth and reliable system operation. Measuring couplings are now standard in hydraulic systems and are widely used. The VOSS VOSSPointDC measuring couplings enable virtually leak-free connection and disconnection of measuring and testing devices or the connection of devices for filling or venting during system operation.

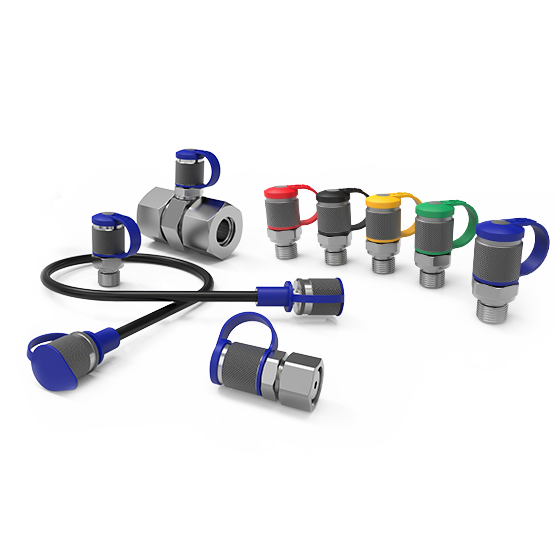

Colorful variety

VOSSPointDC is convincing down to the last detail. For improved identification, the sealing caps are color-coded, which ensures optimum orientation for the user within the hydraulic system. With an integrated plastic element, these ensure a permanently secure fastening. This prevents the cap from coming loose due to vibrations. Corrosion or torn chains are also a thing of the past. As standard, the plastic tab is colored blue, making the connection options within complex hydraulic systems clearly visible to the user. Other basic colors or individual coloring to visually differentiate between several hydraulic circuits are available on request.

Leakage safety

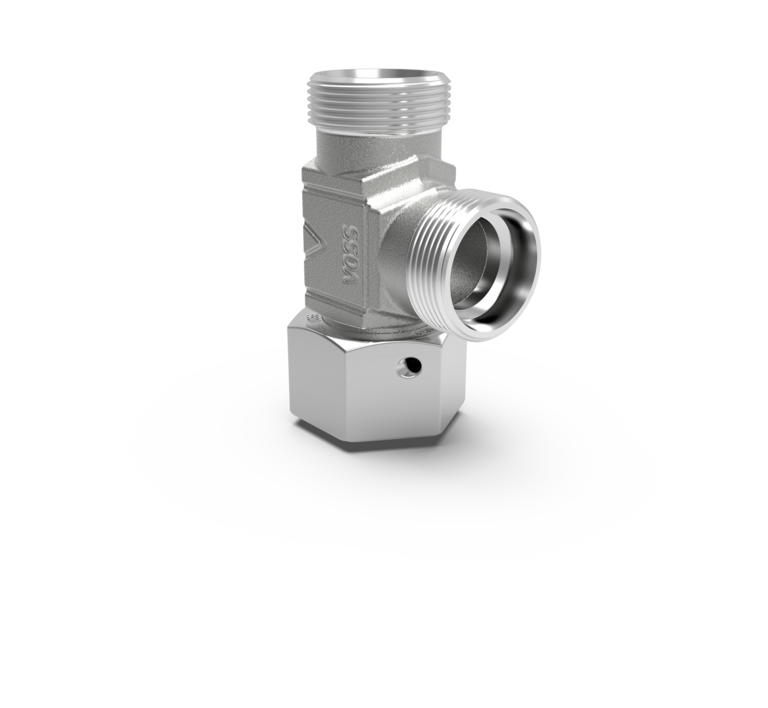

For a 100% secure seal, we use a combination of a metal seal and an elastomer seal on the primary seal. To increase leakage safety and minimize wear, the sealing point was designed in such a way that unnecessary rolling of the O-ring seal is avoided when opening and closing the couplings.

By providing additional support for the O-ring in the secondary seal, VOSS measuring couplings achieve up to ten times greater long-term sealing. The compact design of the VOSSPointDC couplings has a one-piece housing. This prevents additional leakage paths.

Leaving nothing to chance

Throughout the development of VOSSPointDC, we rigorously tested its durability, functionality, and ease of use to ensure an application-oriented design. We maintain these high standards in series production, where each measuring coupling is tested for functional reliability and leak-tightness before delivery.

Product advantages

Highest leakage safety

Maximum leakage safety due to an additional elastomer seal and avoidance of unnecessary leakage paths due to one-piece housing design

Individual coloring

Colored and durable retaining tab, for quick identification of the oil circles

Permanently safe

Vibration protection of the sealing cap to prevent it from coming loose on its own

Resistant

Protected against water during high-pressure and steam jet cleaning

Corrosion resistance

Highest corrosion resistance due to VOSS coat coating

Technical data

Material

Valve body - VOSS specified special material

Retaining strap - VOSS specified plastic

Max. operating pressure

up to 630 bar

The highlights at a glance

VOSSPointDC - Improve existing

The retaining strap

The plastic element ensures a permanently secure attachment. It prevents unintentional loosening of the cap. As this consists of a single plastic element, corrosion or broken chains are a thing of the past. As standard, the plastic tab is colored blue, making the measuring connections immediately obvious. Other basic colors, or to visually differentiate between different hydraulic circuits, are also available on request.

Outstanding functional fulfillment

Due to an ingenious sealing system consisting of a primary and a secondary seal, VOSSPointDC measuring couplings offer excellent leakage safety and functional fulfillment. The primary seal consists of a combined metallic seal and an elastomer seal, which has been designed to minimize wear. The secondary seal provides additional support for the O-ring and thus ensures up to ten times greater long-term sealing compared to conventional designs.

Confirmed reliability

Extensive testing confirms the application-oriented design of our products. Their superior durability, functionality, and ease of use have been validated through numerous tests.

In addition to other tests, VOSSPointDC passed a static leak test over 160 hours, an endurance impulse test of more than 2 million impulses and a burst pressure test with 4 times the nominal pressure.

Typical applications

Our range of measuring couplings, with a variety of types, connection types and dimensions, is impressive in all applications in which pressures must be measured or systems vented.

Agriculture

Pollution is part of everyday life, especially in agriculture. VOSSPointDC is protected with VOSS coat as standard and is resistant to high-pressure cleaning, UV rays and many aggressive media.

Construction machinery

In construction machinery, the hydraulic system has to perform countless different operations. This requires various control circuits with different pressures. With VOSSPointDC, these measuring points can be easily marked in color.

Power unit construction

To ensure correct operation, the system must be completely bled every time the closed hydraulic circuit is opened. VOSSPointDC measuring couplings can also be used to fill or bleed the hydraulic system during commissioning.

Matching products

Pressure testing in hydraulic systems is extremely important for smooth and reliable system operation. VOSS measuring couplings are therefore part of our standard product range. We also offer: