Flaring system BV-10

The VOSS BV-10 flaring fitting based on the proven 10° flare principle demonstrates maximum safety, especially under high loads such as pressure surges, vibrations and alternating bending moments.

When developing the BV-10 flaring system, the proven properties of our ZAKO flange system were adapted to the 24° tube couplings. The result is a flaring fitting that can withstand the most extreme loads.

Due to the wide tube support, the VOSS BV-10 flaring fittings prove their great functional efficiency, especially with high pressure surges, vibrations and alternating bending moments. They are used in applications where other tube connection systems are unable to perform effectively.

The gentle 10° flaring angle prevents overstretching of the tube, which prevents fatigue fractures. Added to this is the excellent holding function on the tube, which is achieved by combining the 10° flare principle with the clamping ring principle. The sealing function is achieved by a very high surface pressure and supporting clamping grooves on the flaring zone. The proven DKO sealing head of the flared cone ensures excellent leakage safety on the fitting body. This seals securely by means of a metallic sealing function and an additional fully chambered soft seal.

VOSS BV-10 flaring fittings are quick and easy to install and function more reliably and economically than welded connections. They are based on the

use of DIN/ISO standardized threaded connectors with 24° cone. This ensures easy interchangeability with cutting ring and welding nipple systems. The extremely robust system is also suitable as a repair solution for cutting ring connections.

Product advantages

Highest leakage safety

Maximum leakage safety due to metallic seal with additional soft seal

Extreme longevity

Incision-free tube retention due to the proven 10° flaring principle.

Extremely robust

The high holding forces and wide tube support make the system particularly suitable for extreme loads.

Flexible in use

Complete range of fittings available in the L and S series and also suitable for stainless steel lines (in accordance with DIN EN 10305-1)

Reduced workload

Easy installation even with thick-walled tubes

Repair solution for cutting rings

Use as a repair solution for defective cutting ring connections

Technische Daten

Material

VOSS specified special material

Max. operating pressure

Up to 500 bar in the "L" series, up to 800 bar in the "S" series

Dimensions

For steel and stainless steel tubes - tube OD 6mm - 42mm

Details at a glance

Impressive information on a safer and more durable alternative

Leak-proof, even under the most extreme conditions

The sealing effect on the tube connection side is achieved by surface pressure in the flaring zone and the labyrinth sealing effect of the "saw teeth" on the conical surface.

The clamping ring clamps the tube end over a wide area on the flaring cone, thus ensuring particularly high holding forces. This means that vibrations and bending moments can be effectively managed.

A sustainable and economical alternative

The BV-10 flared union is based on the use of DIN/ISO standardized unions with a 24° cone. The proven DKO sealing head of the flared cone performs the sealing function on the nozzle. On the tube connection side, the sealing function is achieved by a very high surface pressure and supporting clamping grooves on the flaring zone.

The system for repairing old cutting ring connections

The BV-10 flaring system can be used as a repair solution for cutting ring connections. Tubes with leaking cutting ring connections can therefore be repaired and reused without hesitation.

Product videos and CAD data

Discover the benefits and assembly information of our innovative products in video format and access our extensive CAD database - free of charge and in the highest quality.

Please always observe the current operating and assembly instructions when handling VOSS preassembly devices, tools and products.

Typical applications

The 10° flaring system offers maximum leakage safety under extreme loads.

Mining machine

When reliable performance under the most demanding dynamic bending fatigue conditions is required.

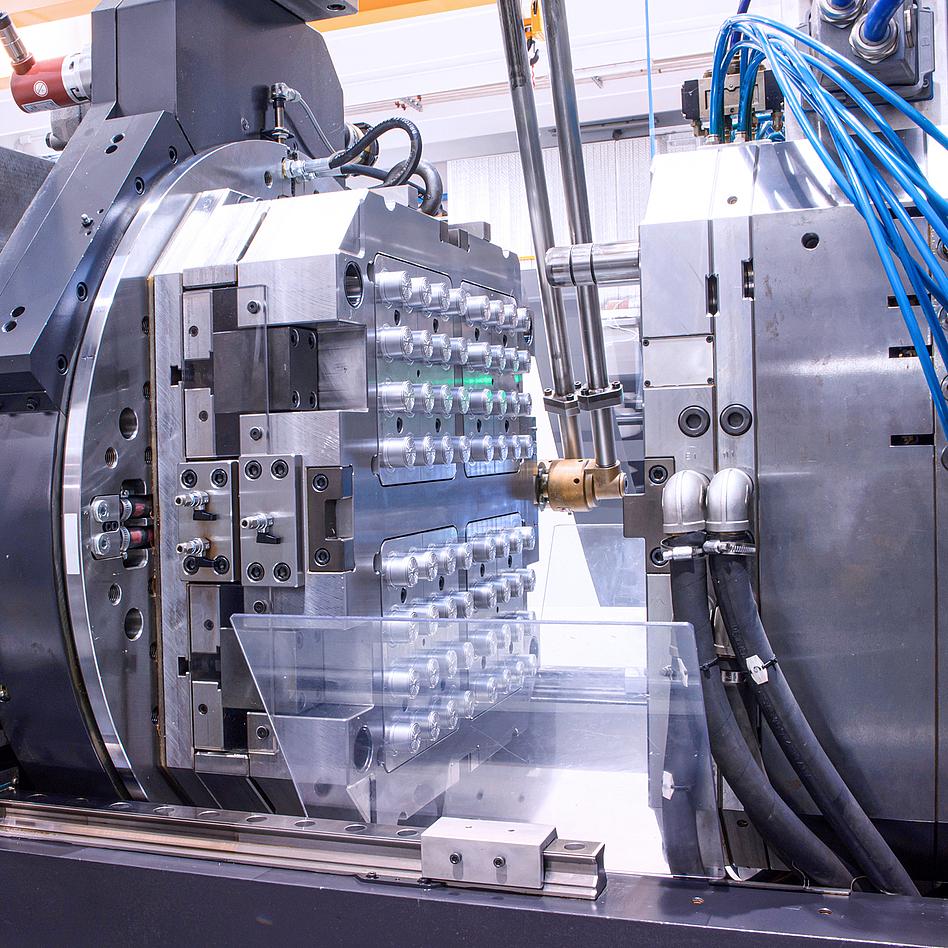

Plastic machines

When secure connections are required with constant load changes and pressure peaks.

Forestry

The robust connection solution when it comes to maximum reliability under mechanical loads.