Flange connection ZAKO

ZAKO is designed for all applications with the highest dynamic loads and special demands on safety and reliability. The flange system has been developed as a detachable, reassemblable alternative to conventional welded joints and is highly cost-effective due to its many advantages.

ZAKO flange connections are based on the 10° flare principle and are available in both SAE and square flange connection geometries.

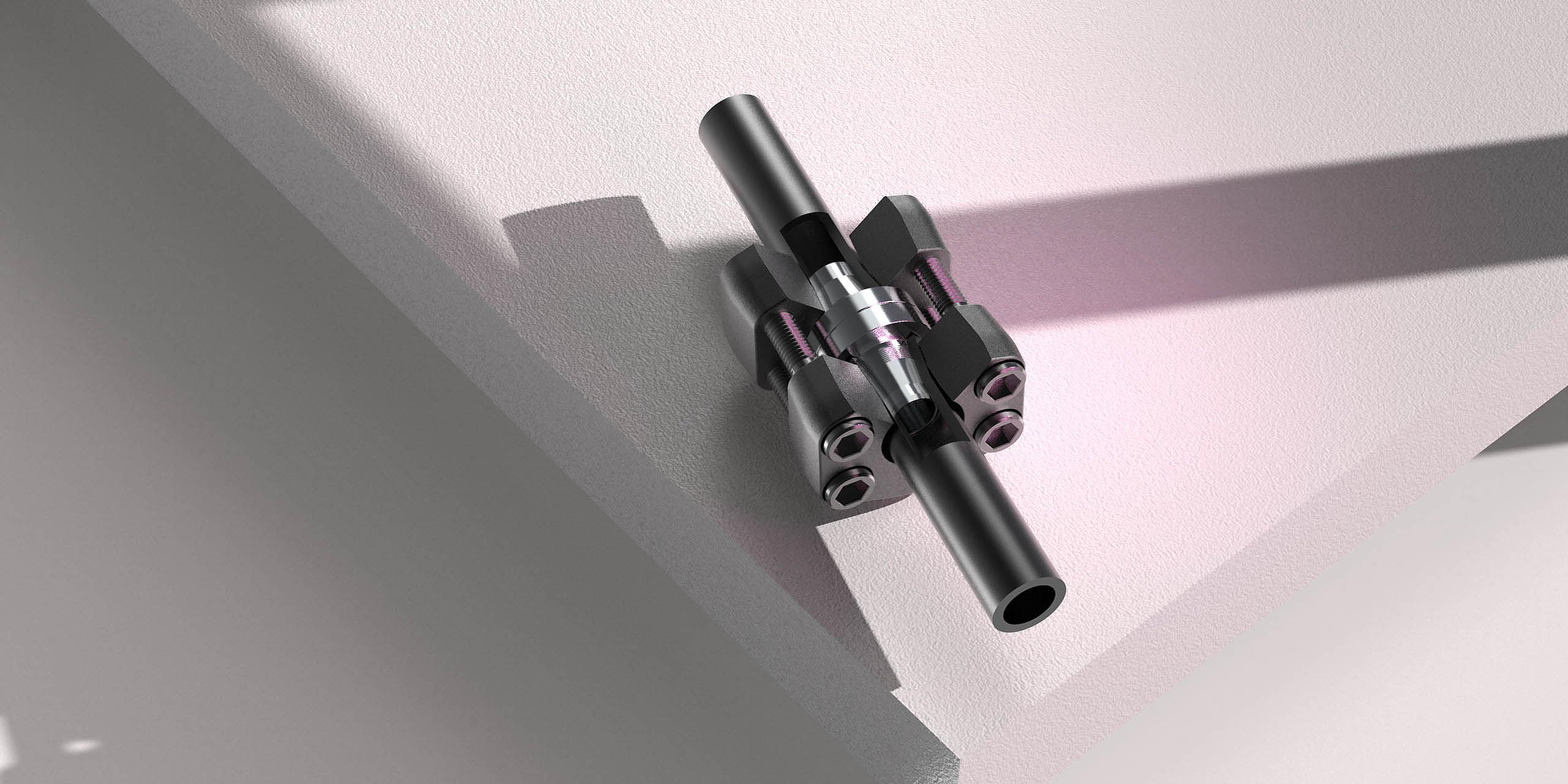

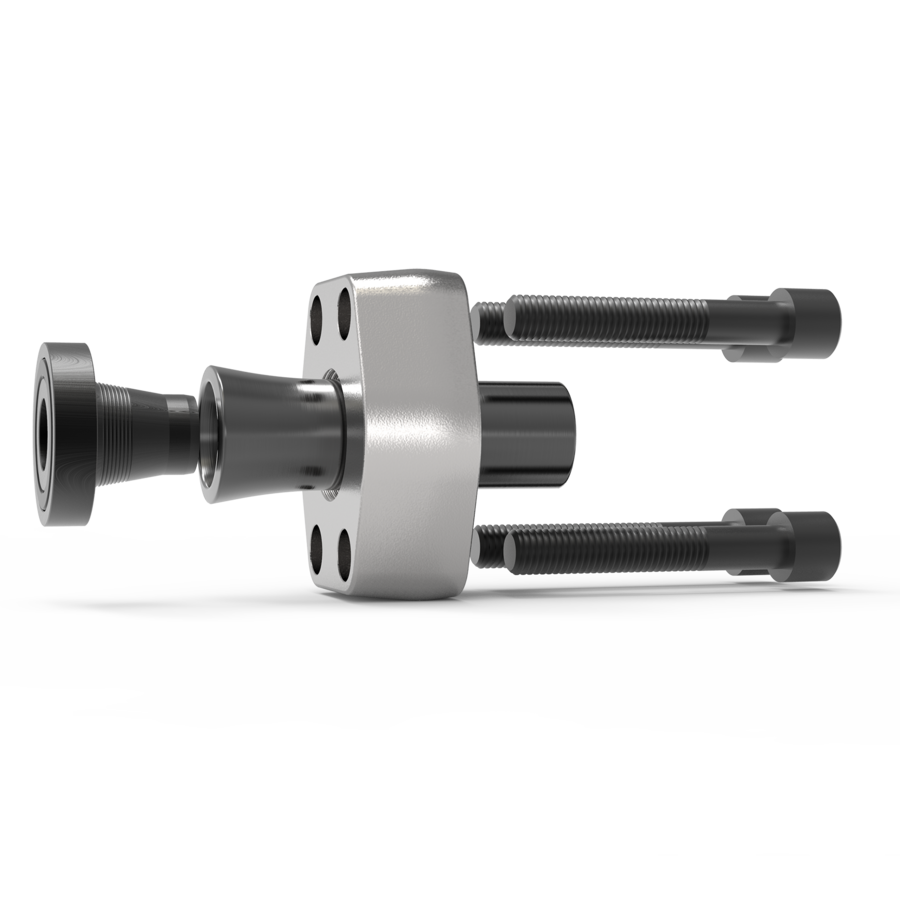

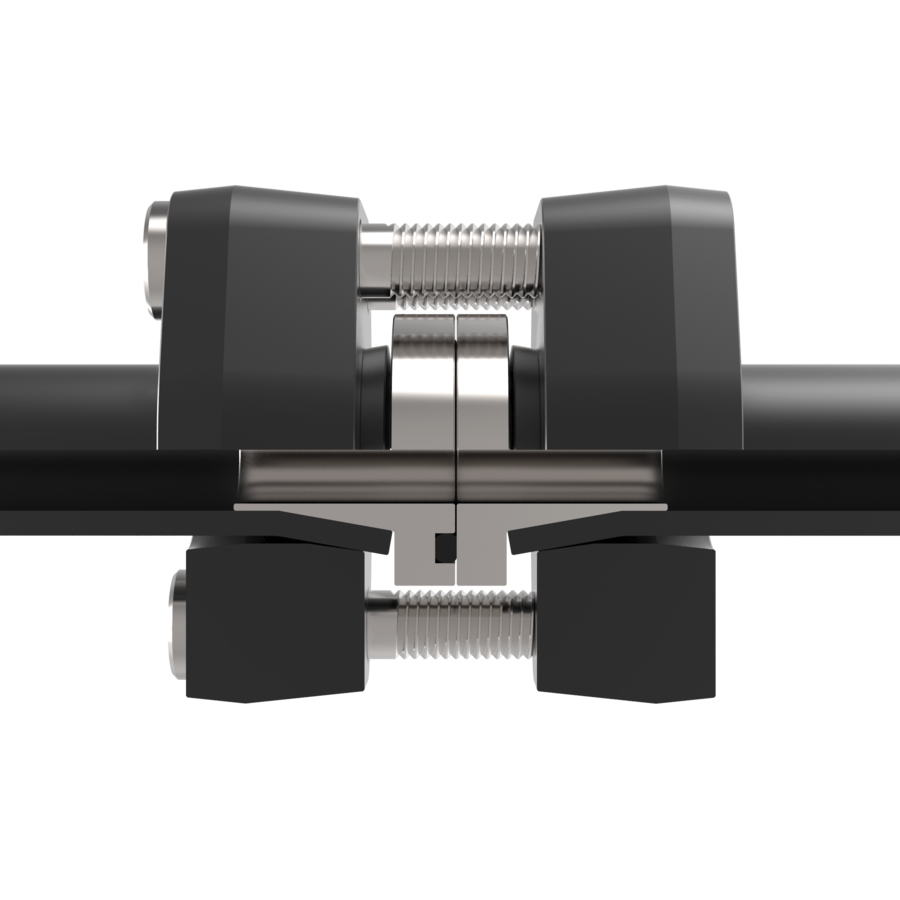

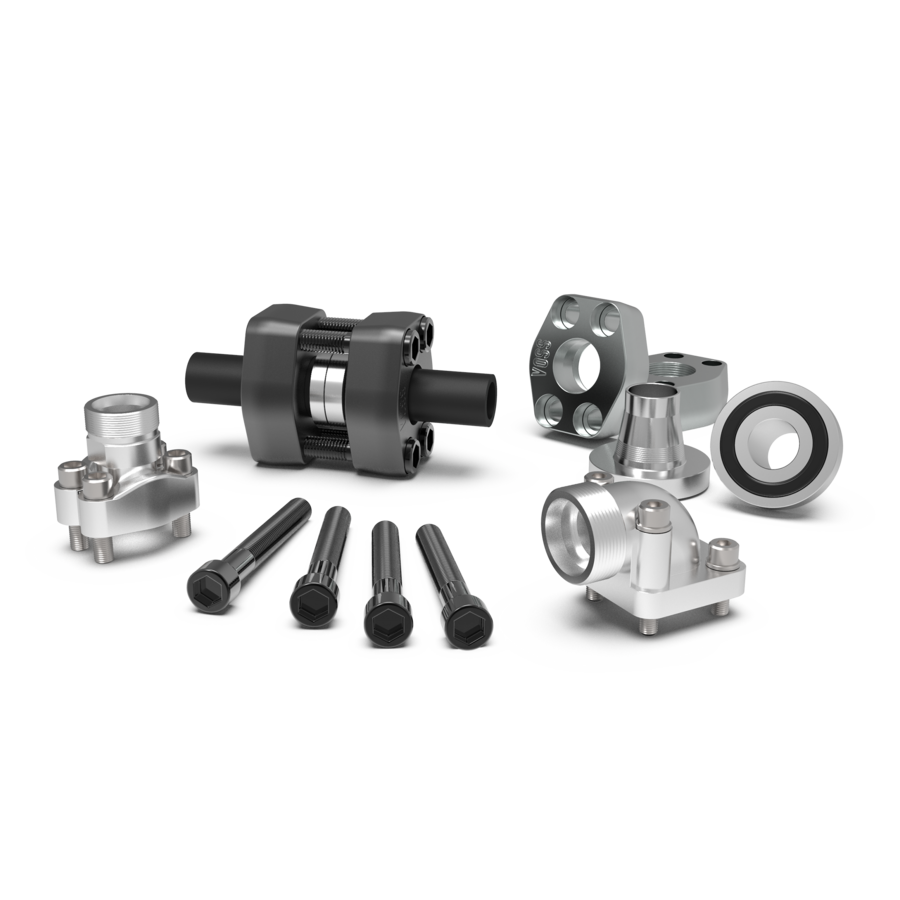

The ZAKO system consists of four optimally coordinated elements:

- The collar ring, which is pressed into the tube using a hydraulic preassembly device and flares the tube by 10°.

- A chambered O-ring, which provides additional safety to the metallic seal.

- The flange as SAE or square version.

- The connecting screws that connect the system permanently and securely.

The flange connection is very easy to dismantle for maintenance or servicing work and is available for tube outside diameters from 16 to 114.3 millimeters with different wall thicknesses.

Product advantages

Extreme robustness

VOSS ZAKO flange connections are based on the VOSS 10° flaring principle, in which the material is not overstretched and remains elastic enough to withstand even the highest to compensate for bending fatigue stresses.

Maximum longevity

The notch- and incision-free tube support ensures long-term stability and tightness of the entire system. All metal sealing zones are protected against leakage by an additional soft seal or sawtooth seal.

Guaranteed process reliability

When installing a ZAKO flange connection, the collar ring remains in the flanged tube. Errors caused by tool wear have been eliminated as a potential factor.

Maximum flexibility

The VOSS ZAKO flange range offers maximum flexibility for tube diameters of up to 114.3 mm and is available with square or standard hole patterns according to SAE in 3000 psi or 6000 psi.

Economical overall concept

The ZAKO detachable flange system eliminates the need for time-consuming welding and saves a lot of time and money. The simple assembly eliminates the need for time-consuming work steps such as tacking, setting up, seal welding, cleaning and flame straightening.

Corrosion protection in perfection

VOSS coat is the zinc-nickel-based surface protection that optimally protects the ZAKO flange range against corrosion.

Technical data

Material

VOSS-specified special material with VOSS coat surface protection or blackened, oiled or burnished.

Max. operating pressure

In the standard series up to 250 bar and in the high-pressure series up to 400 bar with 4-fold safety

Dimensions

For steel tubes with outer tube diameters of 16 mm - 114.3 mm

Details at a glance

Find out more about the advantages of our flange connection ZAKO

Perfectly designed for efficient assembly

In hydraulic connection technology, the ZAKO flange range stands for reliability on a large scale. Due to its unique design, it not only withstands the toughest loads with ease, but it is also designed for large tube diameters. With their 10° flare system and exclusive zinc-nickel coating for maximum corrosion protection, ZAKO flanges are the benchmark in all areas of hydraulics and prove their performance in open-cast mining, hydraulic presses and injection molding machines, for example.

10° flaring principle for maximum reliability

Compared to the conventional flaring angle of 37°, ZAKO flange systems use an angle of 10° with small saw teeth in the flaring zone. Our many years of experience with this system and extensive force measurements show considerable advantages in terms of the stability and safety of the connection. By expanding the tube by just 10°, the material is also not overstretched and therefore remains elastic enough to compensate for even the highest bending fatigue stresses.

The full range of quality and safety

The ZAKO flange system is available for tube diameters from 16 to 114.3 mm with different wall thicknesses up to 17 millimeters. All dimensions are available with standard hole patterns according to SAE (3000 psi / 6000 psi) and square flanges. The ZAKO range can be loaded up to 250 bar in the standard series and up to 400 bar in the high-pressure series with 4-fold safety.

Product videos and CAD data

Discover the benefits and assembly information of our innovative products in video format and access our extensive CAD database - free of charge and in the highest quality.

Please always observe the current operating and assembly instructions when handling VOSS preassembly devices, tools and products.

Typical applications

The 10° flaring system offers maximum leakage safety under extreme loads.

Mining machine

Extreme loads and high pressures with a large volume flow are in mining applications present all hydraulic components with special challenges. The ZAKO flange system is specially designed for these applications and guarantees maximum reliability.

Marine and offshore

Whether in shipbuilding or in the offshore industry, i.e. on gas or oil platforms the ZAKO system is easy to install on site, the high level of safety and, due to the VOSS zinc-nickel corrosion protection, ideal for the suitable for heavy-duty use on the high seas and can withstand extreme bending forces and reliably withstand the aggressive salt water.

Stationary systems

The largest pressing plants in the world develop an incredible 90.000 kN of pressing pressure. Car body construction. But enormous forces are also needed in other industrial sectors be mastered. This is where ZAKO systems demonstrate their performance and combine efficient assembly and flexible disassembly, e.g. for maintenance work, with maximum reliability and safety.

Matching products

Our approach is holistic. In addition to a wide range of suitable connection components, VOSS offers an extensive portfolio of preassembly devices, tools and aids.