Cutting ring VOSSRingM

The VOSS Ring M raises cutting ring connections to a new level of quality and safety due to its simple assembly and high leakage resistance.

When developing the VOSSRingM, the experience gained from over 90 years of connection technology was used to completely redesign the metal-sealing cutting ring. Our development engineers took nothing for granted and completely rethought the entire design, material and assembly behavior.

The improved cutting-edge geometry and the special surface hardening ensure ideal cutting on the tube. In addition, geometric reinforcements increase the pressure resistance, and the patented block stop facilitates professional preassembly.

Product advantages

The VOSSRingM cutting ring system offers all the advantages of an earlier 24° cutting ring fitting and raises it to a new level of quality and safety.

Highest leakage safety

Maximum leakage safety of the cutting ring fitting due to optimum tube incision

Highest pressure resistance

Highest pressure resistance due to geometric reinforcements

Dynamic load capacity

Very good dynamic load capacity due to VOSS-specified material

Process reliability in assembly

Increased process reliability in assembly due to patented stop concept

Reduced workload

Reduced workload due to reduced tightening paths

Reduction of incorrect assembly

Reduced influence of incorrect assembly due to wear-free preassembly tools

Technical data

Material

VOSS specified special material

Max. operating pressure

Up to 500 bar in the "L" series, up to 800 bar in the "S" series

Dimensions

For steel and stainless-steel tubes - tube OD 6mm - 42mm

Further information

Details at a glance

Find out more about the advantages of our cutting ring VOSSRingM.

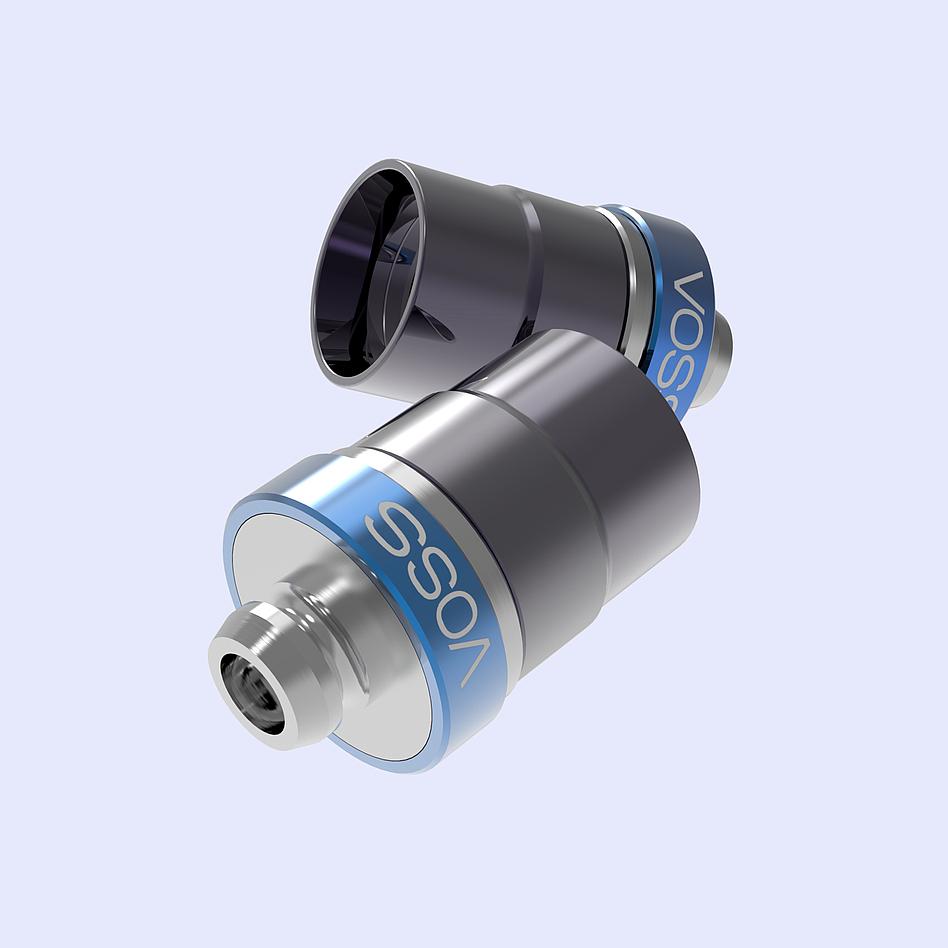

Reduce assembly times and prevent errors

The innovative VOSS ring preassembly socket, which enables even inexperienced personnel to carry out precision work due to its patented stop function, provides added safety. In the event of over-assembly, the torque increases noticeably, reliably preventing assembly errors. In addition, due to the VOSS ring preassembly support, the final assembly path is reduced from 90° to 30°. This also reduces the installation time by around half. This advantage is particularly useful in difficult installation conditions, such as overhead installation, in ergonomically unfavorable positions or in particularly tight installation spaces.

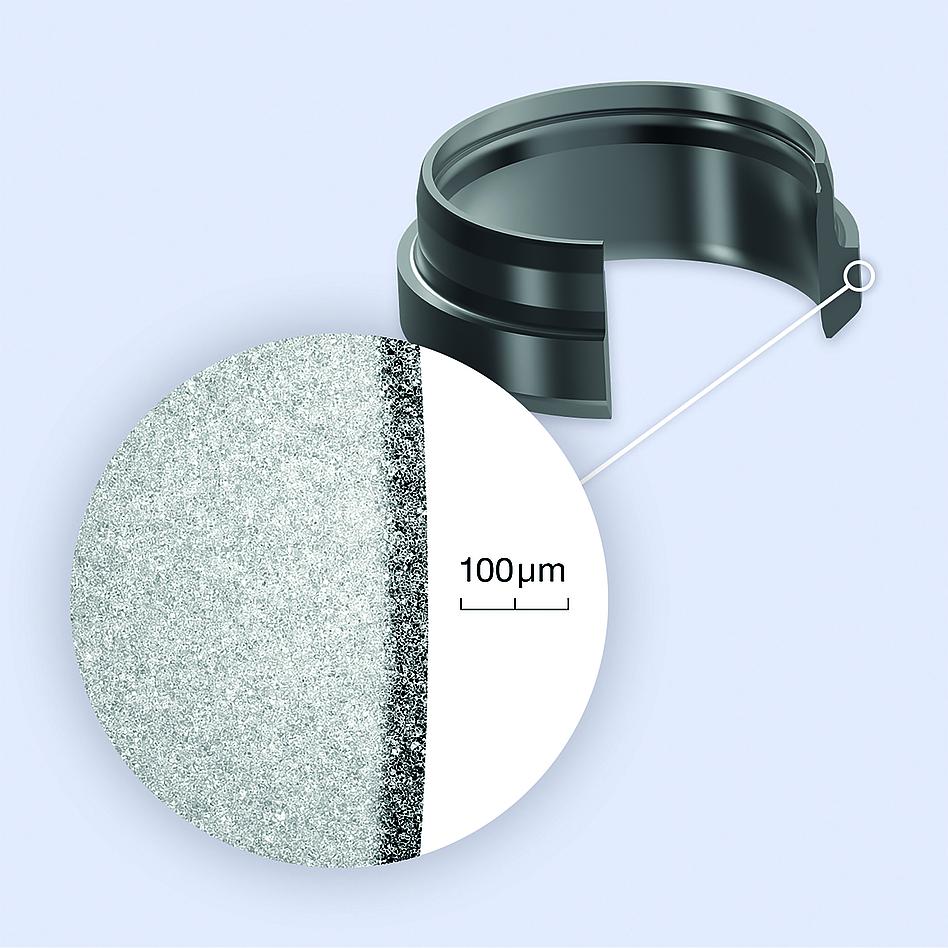

A cutting ring that cuts into steel and stainless-steel tubes

For our cutting rings, we use a specially developed special material with very narrow tolerances for the alloy components. This ensures high strength of the extremely homogeneous, fine-grained structure with high toughness and fracture resistance. Our optimized hardening process produces a very thin and extremely hard surface layer. This ensures precise and optimum cutting in steel and stainless steel. Stainless steel tubes.

Assembly videos

You can find interesting information on installing our products here in video format. Please always observe the current operating and assembly instructions when handling VOSS preassembly devices, tools and products.

Typical applications

The metal-sealing VOSSRingM cutting ring offers maximum functionality and leakage safety for a wide range of applications.

Agriculture

The VOSSRingM is the optimum connection solution when maximum leakage safety and corrosion protection are required.

Trains

Due to the innovative special hardening of the VOSSRingM, it also offers maximum leakage safety when used with stainless steel tubes.

Construction machinery

The innovative design principle makes the VOSSRingM particularly resistant to dynamic alternating bending loads and pressure pulses.

Matching products

Our approach is holistic. In addition to a wide range of suitable connection components, VOSS offers an extensive portfolio of preassembly devices, tools and aids.