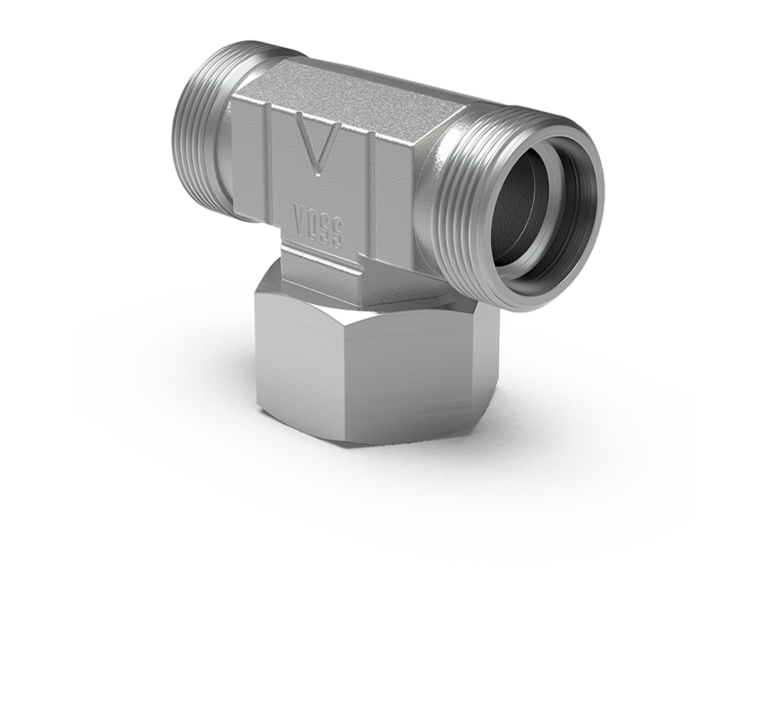

Check valves

VOSS check valves are characterized by their particularly flow-optimized design and are available in a variety of versions for a wide range of applications.

The non-return and shut-off valves are offered in various formats: as insert cartridges for block designs, for installation in tubes, or as loose installation kits for use in valves and blocks.

All variants impress with their flow-optimized design and the chambered soft seal on the sealing cone as well as hydraulic end position damping. This minimizes noise, enables particularly low-resistance flow values and achieves leakage-free shut-offs.

Product advantages

- Best flow rates due to flow-optimized design of the internal parts

- Hydraulic end position damping ensures low-noise operation

- Wear minimization through stroke limitation of the valve tappet

- Chambered soft seal on the metal sealing cone for maximum leakage safety

- Large product range for a variety of applications

- VOSS coat corrosion protection as standard surface protection

Technical data

Material

VOSS specified special material with VOSS coat surface protection

Max. operating pressure

Up to 630 bar depending on version

Dimensions

For steel tubes - tube OD 6mm - 42mm

Typical applications

VOSS check valves offer the greatest possible flexibility with a large number of variants.

Mining machinery

When it comes to reliable performance under the toughest conditions. VOSS check valves are wear-resistant and optimally protected against corrosion.

Tool machines

When maximum efficiency and precision are required, VOSS check valves offer the right alternative.

Forestry

The low-wear and flow-optimized VOSS check valves offer maximum functional performance and precision even under the toughest working conditions.

Matching products

Our approach is holistic. In addition to a wide range of suitable connection components, VOSS offers an extensive portfolio of preassembly devices, tools and aids.