VOSSPlug: Hydraulic Hose Plug-In System for Tight Assembly Spaces

VOSSPlug: Hydraulic Hose Plug-In System for Tight Assembly Spaces

Efficiency and reliability play a central role in hydraulic connection technology. This means that the focus on error-free work and optimal use of time resources is increasing. With the development of VOSSPlug, we have created an innovative solution for applications that meet these challenges.

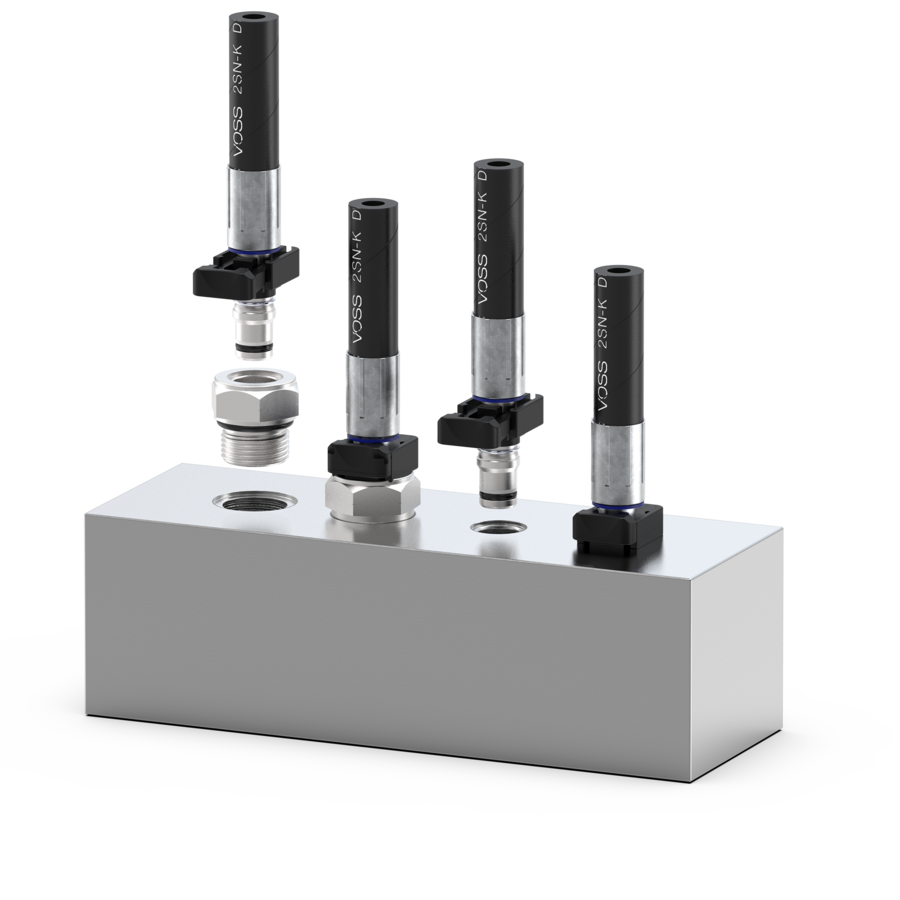

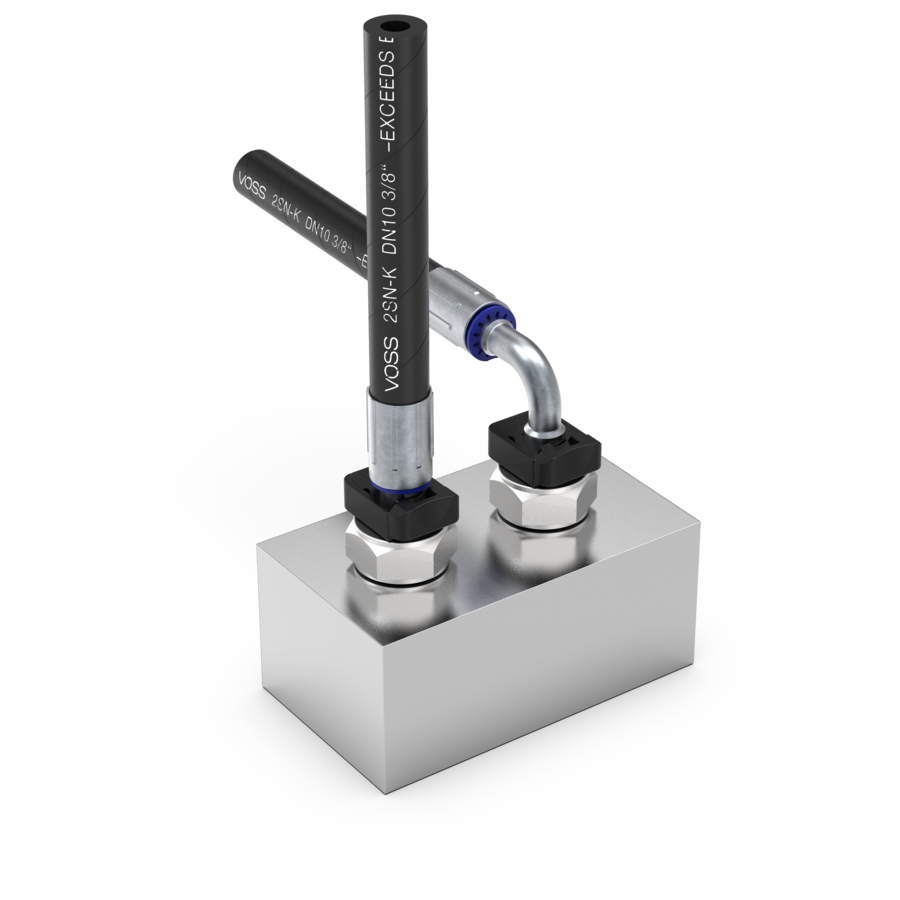

While traditional screw connections often reach their limits in tight installation spaces, VOSSPlug offers a space-saving alternative as a plug-in connection system. At the same time, the connector meets the high safety requirements of conventional screw connections and enables efficient installation even under demanding conditions.

Challenges of Conventional Screw Connections

Screw connections are a well-established standard in hydraulic systems. However, their use is increasingly challenged by the ever-tightening installation spaces in modern machines. Limited radial space makes assembly with a wrench cumbersome, as it must be repositioned multiple times to tighten or loosen nuts. This not only increases the time required but can also lead to potential issues such as turning and stress on the hoses. A plug-in system provides the solution to these challenges.

VOSSPlug: Simple, Fast, and Secure

VOSSPlug is specifically developed to meet the challenges of modern hydraulic systems, combining innovative technology with easy handling.

The assembly of VOSSPlug is remarkably simple and consists of just two steps: First, the connector is inserted fully to the stop. Then, the system locks automatically with a simple press of the patented wedge slider. The visible locking mechanism provides additional safety and ensures reliable control.

Thanks to tool-free installation, common error sources—such as insufficient tightening or incorrect torque—are completely eliminated. This significantly increases process reliability, making assembly not only safer but also more efficient. Compared to conventional screw connections, installation with VOSSPlug is at least ten times faster.

Disassembly is just as quick and uncomplicated: Once the system is free of pressure, the wedge slider can be released using a standard screwdriver. The connector is then simply moved three millimeters against the pressure direction to fully disconnect the plug-in system. The 360-degree chambered retaining element prevents accidental unlocking and minimizes the risk of leaks or assembly errors.

Successful Tests in Practice

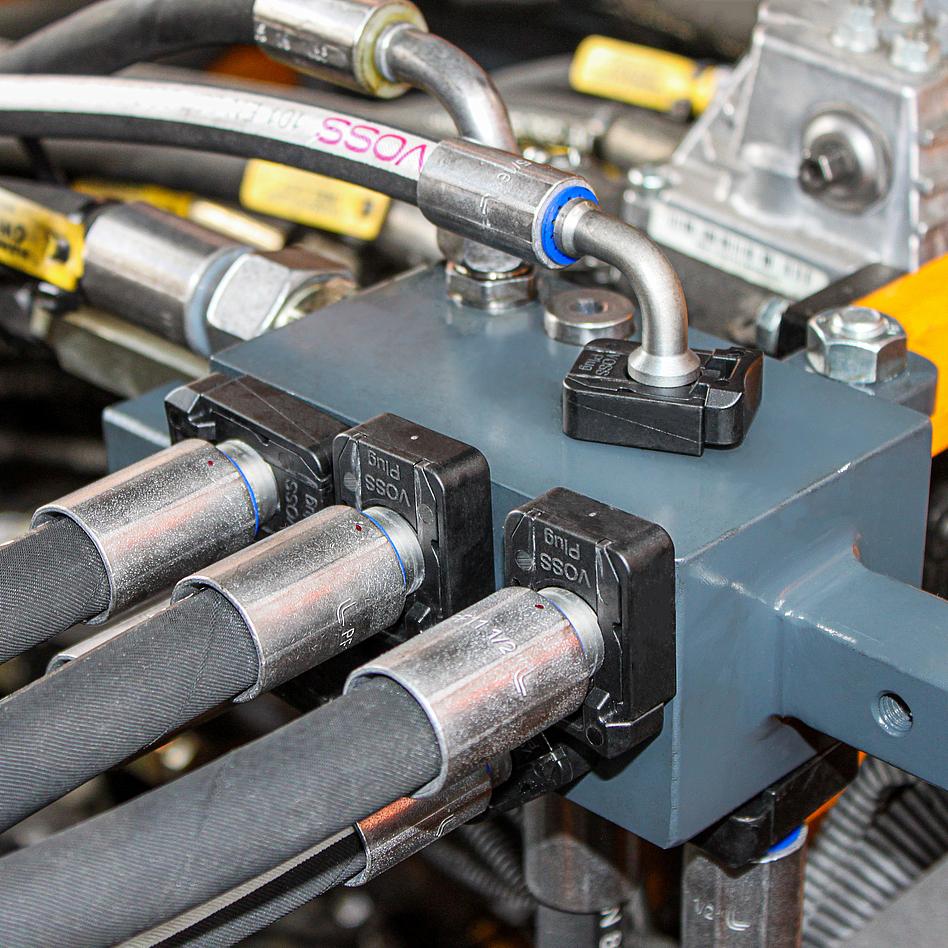

In a three-month field trial, the advantages of VOSSPlug were tested under real-world conditions at a partner company specializing in heavy-duty forklifts. The results were compelling: Using the plug-in systems significantly reduced assembly time, optimized space utilization, and improved maintenance efficiency. Multiple practical tests confirmed that even after 100 plug-in cycles, the sealing and functionality remained unchanged.

The Future of Connection Technology: Plug Instead of Screw

Screw connections remain the standard for high-pressure applications. However, in mobile applications operating at pressures between 200 and 350 bar, where space is limited, VOSSPlug truly showcases its strengths. This pioneering plug-in hose system ensures both reliable safety and efficient assembly with a pressure resistance of up to 400 bar. VOSSPlug is more than just an alternative to screw connections—it is a milestone in connection technology.

For What?

- Connecting hoses, especially in hydraulic applications

- Tight and limited radial installation spaces

- Assembly processes under high time pressure

For Whom?

- Production managers

- Assembly staff

Why is it great?

- Up to 10 times faster than traditional screw fittings

- Easy handling without special tools

- Shorter assembly times and minimized error risk

- Reliable even under high pressure

- A solution for the challenges of modern assembly