Immersion Cooling: The Future of Battery Cooling Technology in Electric Vehicles

Battery modules can be cooled in various ways. In addition to conventional cooling plate technology, immersion cooling presents an alternative solution.

Immersion Cooling: The Future of Battery Cooling Technology in Electric Vehicles

Battery modules can be cooled in various ways. In addition to conventional cooling plate technology, immersion cooling presents an alternative solution. Immersion cooling is a promising answer to achieving faster charging times and greater range for lithium-ion batteries in electric vehicles. At VOSS, we offer comprehensive thermal management system solutions for immersion cooled battery modules.

The Challenge: Optimal Temperature, Sealing, and Limited Space

For a battery to perform at its best, it must maintain a temperature of approximately 25 °C. This ensures that electric and hybrid vehicles can achieve maximum range and performance. Therefore, batteries need to be conditioned to their specific operating environment regardless of external temperatures.

When working with liquids, ensuring leakage free sealing poses a significant challenge. Additionally, easy to assemble and disassemble connection technology is essential. Given the limited installation space and weight constraints, compact and lightweight components are required.

What Is Immersion Cooling, and How Does It Work?

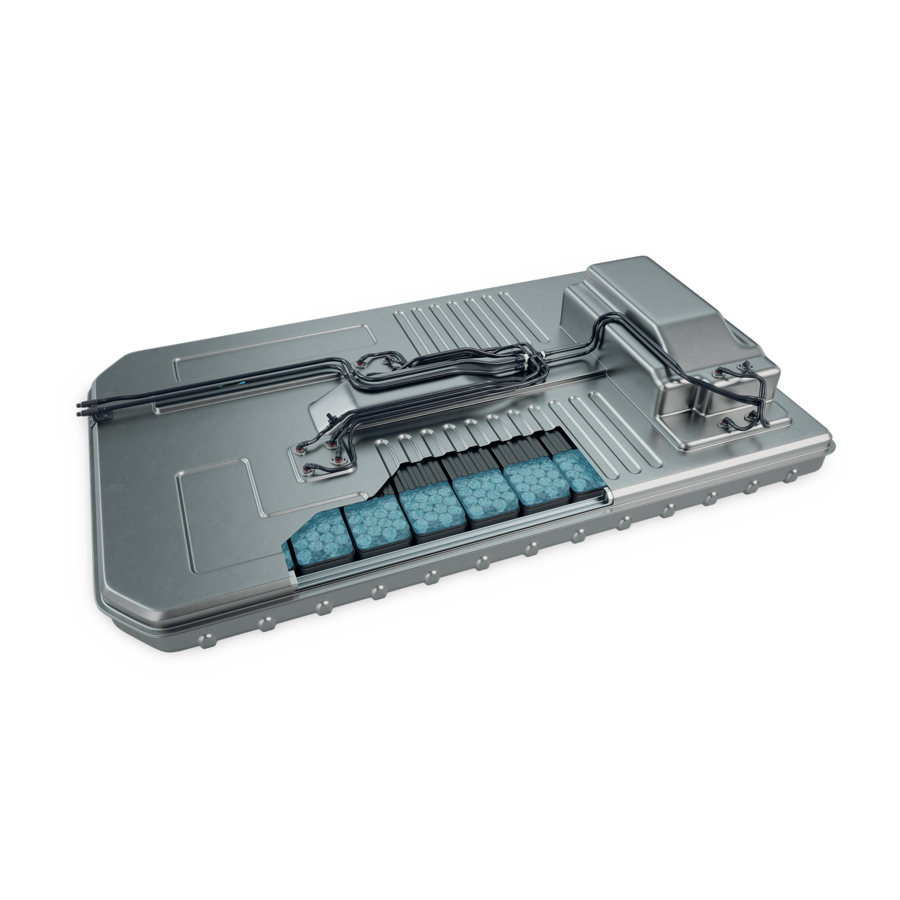

The cooling plate is the standard method for battery cooling in electric vehicles. It circulates a coolant that transfers heat away through fluid-conducting systems, strictly separating the coolant from the battery cells. Immersion cooling takes a different approach. In this method, battery cells are immersed in an electrically non-conductive cooling liquid – hence the name immersion cooling – and are surrounded by this fluid. This allows heat to be directly conditioned at the cells, ensuring a more even temperature distribution and more efficient heat dissipation within the battery.

Immersion cooling addresses the significant challenge of maintaining uniform temperature distribution across all battery cells. It reduces the risk of hotspots and fire hazards while increasing overall battery performance and lifespan. The direct integration of cooling with the battery cells also allows for a more compact system, saving both space and weight.

Another consideration with immersion cooling is the accessibility of modules during assembly and maintenance. At VOSS, we have developed secure, leak-free, and easy-to-install fluid systems, offering practical solutions for our customers.

The Solution: VOSS quick connect system 272

At VOSS, we specialize in the development and production of line and connection systems for immersion cooling technology. Our product solutions use electrically conductive materials that prevent static buildup caused by constant friction between plastic tubing and liquid, safely discharging the resulting static to a grounding point. Safety against material washout, which can lead to increased conductivity of the medium, also plays a major role in the choice of material. Therefore, we rely on fiber-reinforced, recyclable plastics, which also contribute to weight reduction.

Cooling circuits using liquid mediums are often highly complex, involving an increasing number of components and fluidic interfaces. Ensuring the safe assembly and handling of these numerous connections is critical in battery-electric vehicles. As the complexity of circuits grows, available space within the electric vehicle decreases. Compact components must be adapted to the specific installation space. The VOSS quick connect system 272 meets all these criteria. It features optimized handling and enables quick and secure connections for coolant lines.

Many quick connect systems available on the market require high insertion forces, particularly with larger dimensions, which do not meet OEM ergonomic requirements. This often necessitates greasing seals or replacing them with custom seals. We addressed these challenges with the VOSS quick connect system 272 by using a wave-shaped standard O-ring, solving these issues effectively.

The Advantage: Double Flow Stop Valve

For our fluid system, VOSS uses a new compact and robust double flow stop valve. This ensures leak-free replacement or maintenance of battery modules and cooling circuit components. The valve is compatible with various VOSS quick connect systems and their counter-contour, automatically opening and closing during connection and disconnection of the quick connect system. This prevents the coolant medium from leaking.

The double flow stop valve is user-friendly, suitable for tight spaces, and guarantees consistent flow with minimal pressure loss.

Future Developments in E-Mobility

We are currently collaborating on advanced projects with an international sports car manufacturer and an agricultural machinery producer, showcasing the diverse and broad application potential of immersion cooling. The ongoing development of immersion cooling could significantly impact e-mobility. It already offers shorter charging times, enhanced safety, and more resource-efficient battery production.

The growing demand for high-performance and eco-friendly electric vehicles indicates that immersion cooling is likely to play a key role in shaping the future of sustainable mobility.

For what?

- Cooling plate technology for liquid-cooled battery modules

- Line and connection systems for immersion cooling technology

For whom?

- Designers and developers seeking advancements and solutions in EV cooling technology

Why is it great?

- Easy and fast assembly and disassembly

- Space- and weight-saving components

- Electrically conductive systems to prevent static buildup

- Immersion cooling – a promising solution to improve the performance and safety of lithium-ion batteries