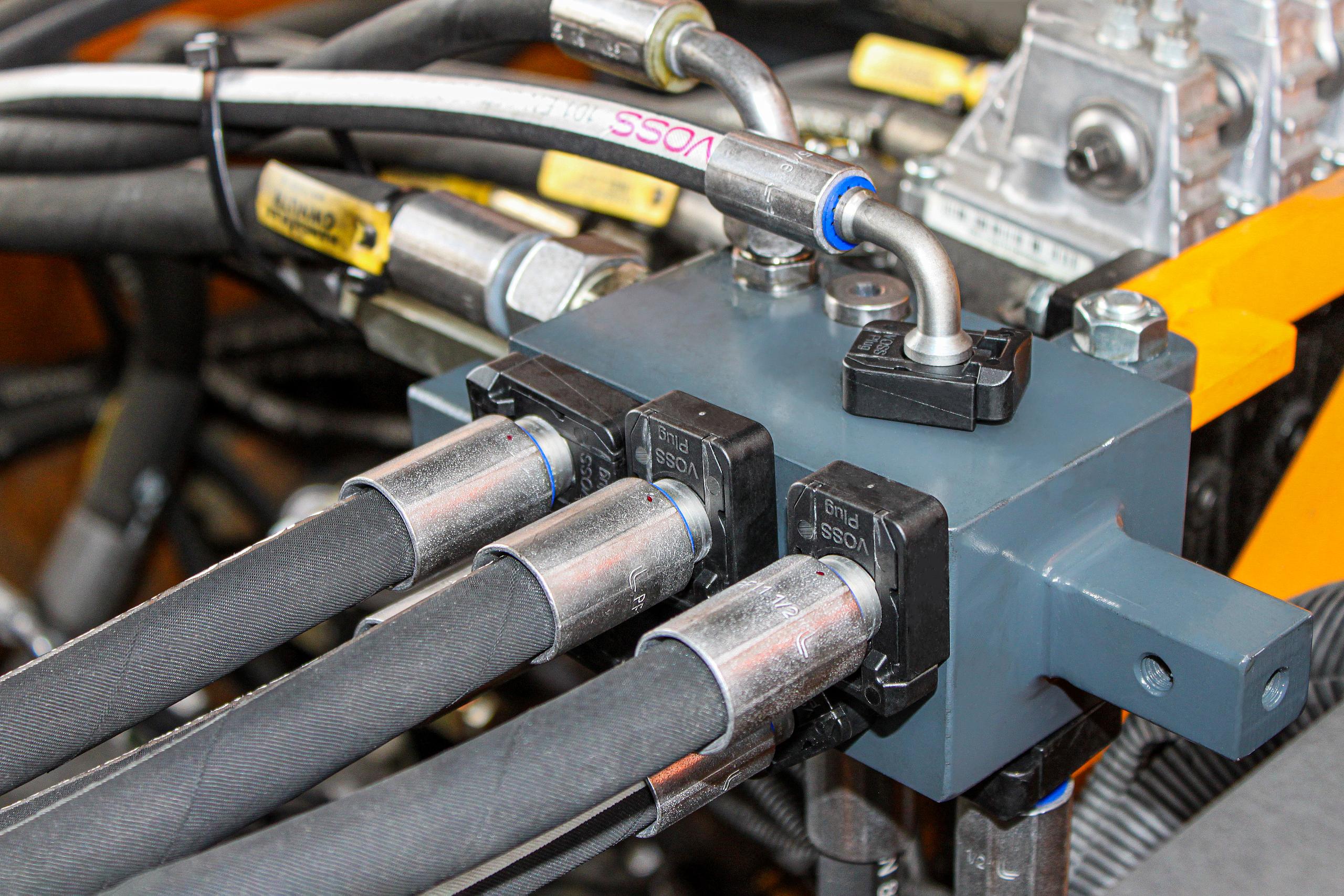

Hydraulic connection technology in heavy-duty forklifts: M Fahrzeugbau relies on VOSSPlug

Our VOSS Plug system has to prove itself in a test phase lasting several months at the Westerwald forklift manufacturer M Fahrzeugbau. The requirements of the hydraulics in heavy-duty forklifts are high and there is often a lack of solutions that are easy to assemble and dismantle for maintenance purposes and that also ensure a high level of leakage protection. This is where VOSS Plug comes into play, which is made precisely for such systems.

VOSSPlug

As a manufacturer of heavy-duty forklifts, the company M Fahrzeugbau has a claim to safety and accuracy in the connection technology of its hydraulic systems - especially with these forklift monsters like the ones the company produces. In hydraulic connection technology, screwing solutions have proven themselves for safe and leak-free assembly. However, there are always situations in which they reveal weaknesses - for example in hydraulic systems in forklifts, where space is always limited and difficult to access even afterwards. Little room for maneuver and the limited accessibility of the screw connections make life difficult for fitters. But especially when a highly specialized vehicle breaks down, it is important to act quickly because there are usually no replacement vehicles available and logistics come to a standstill. A reliable connection system is all the more important when transporting heavy loads that involve high pressure and great force.

M Fahrzeugbau has been a sister company of Appenfelder GmbH since 2012, an intralogistics competence center for services relating to industrial trucks, warehouse technology, work platforms, attachment technology and cleaning equipment. With the production of heavy-duty compact forklifts, M Fahrzeugbau serves a niche market in which it knows how to assert itself. Of the average 100 devices that are considered an annual requirement in Europe, around 20 to 30 are sold by M Fahrzeugbau. As a further service, the company also offers individually adapted six to forty ton trucks. In accordance with the high requirements, M Fahrzeugbau was looking for a better solution for their hydraulic connection technology. How practical that we developed VOSS Plug precisely for these types of applications.

Plugged into hydraulic systems instead of screws

Can be installed without tools and simply by plugging in, VOSS Plug not only saves time, but also ensures no leakage and a stable connection system. We attached great importance to tension-free assembly without any directional deviation. VOSS Plug can be installed within five seconds and can also be assembled and dismantled to save space and time. The key to a high pressure load capacity of up to 400 bar is achieved by the plug-in system thanks to our patented wedge slide lock.

This ensures complete 360° clamping of the special snap ring with an active and visible lock. There is also nothing to worry about during dismantling: Even if the system is unlocked while the line is still under pressure, nothing will happen. Only when the fitter moves the plug approximately three millimeters against the pressure direction does the retaining ring assume its open position and he can completely release the plug-in system.

We have prevented directional deviations with a special plug-in technology: it always independently adapts to the ideal, tension-free path of the hose direction. If you would like to do without the adapter socket, we also offer an integrated plug-in version of VOSS Plug. We provide the customer with shaped bores in the connection area of the system, so that the adapter socket is no longer necessary.

Leak-proof connection technology in field tests

M Fahrzeugbau wanted to see the function for itself in a field test over several months. A successful test would mean the comprehensive implementation of VOSS Plug in all of the vehicle manufacturer's machines. So far the use has been going smoothly and M Fahrzeugbau sees VOSS Plug as the ideal system to replace the screw connections. This would make the installation and maintenance of hydraulic connection technology in heavy-duty forklifts much easier in the future.

“We are thrilled with the results so far with VOSS Plug in our vehicles. The new connection technology for hydraulic lines enables us to manufacture more efficiently and in a more customer-oriented manner. With the clip-on system, machines can be maintained more quickly and easily and the installation space is used efficiently. We assume that after the test phase, VOSS Plug is the ideal system for our production,” explains Michael Breunig, Managing Director of Appenfelder GmbH and M Fahrzeugbau GmbH.